Collecting the material that a high-pressure waterjet has dislodged from a surface can be carried out in a number of ways, depending on the scale and volumes of material that have to be removed. One of the initial problems that arise depends on the energy of the jets that are striking the target, and the part of that energy that remains in the water and dislodged particles after the jet impact.

If a surface is relatively smooth (think for example of a ship hull, or the deck or sides of a bridge) then when a jet has hit the surface and removed the small amount of material (such as rust or paint) it will likely continue in a relatively straight line forward, since the surface roughness of the target, while disrupting and flattening the jet, has not sufficient angle to radically change much of the flow of the jet.

Which might make it time for a little recap. One of the experiments that I would run with an introductory undergraduate class was to give each student a high-pressure lance, and then have them hold the nozzle just above a target surface. The pressure of the water being fed to the gun was then slowly raised, and as this occurred the jet went from striking the surface and then just flowing along it, when there was no penetration or surface material removal, to being reflected back at the lance holder.

The reason for this is that, as soon as the jet started penetrating into the material (usually a rock for the purpose of the demonstration) then the water is entering a hole where the only exit is back the way that it came in. It is a salutary lesson for the lance holder since all of a sudden the jet is coming straight back (which is why all the personal protective equipment is an important part of the lesson).

This only holds true where the jet is hitting a relatively flat surface in an approximately normal or perpendicular axis of attack. In the more general case the cut along the surface will cause the water and debris to scatter in a more general spread, and it becomes a more difficult job to collect both back together in a way that allows both to be contained and removed from the site (an increasingly important part of the environmental parts of the process).

There are places, such as steeply dipping coal seams, where the geometry of the excavation itself helps to confine this ejecta and direct it, under gravity, to fall into a narrow space where the water and coal particles are brought together so that the coal is suspended in enough water that it can then be carried away from the work zone.

Perhaps the best example of this was the Sparwood mine in British Columbia in Canada, where the mine was extracting coal from a seam that was roughly 40 ft thick, and which dipped at around a forty degree angle.

Figure 1. Section showing the Sparwood mining plan

Drifts were first run at a slight angle (this started at six degrees, but after lining the flume with Teflon plates the mine was able to reduce this to just over four degrees) to the strike of the seam. This was a sufficient angle that, when all the coal was caught in the flume it would be carried down without settling by the spent water from the mining process, which was also trapped in the underlying drift, and held by a barrier across that drift. The shallower the angle then the more coal could be recovered above the main haulage ways at the back of the working area.

The mining tunnels (drifts) were first driven to the back of the section, using a small road heading machine to extract the coal, while installing a flume along the side of the drift so that the coal could be immediately transported away as it was mined. Full support to the tunnel was also installed using arch girders, with bracing wooden slats between the girders. Once the drift had reached the end of the seam, then a hydraulic monitor was placed in the uppermost drift, and the arch girders and wooden planks removed from the final fifty feet of the tunnel, with the monitor placed under the last few tunnel supports of the remaining tunnel section.

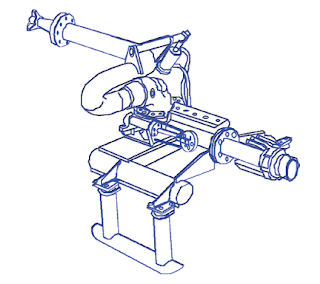

Figure 2. Layour of the monitor within the access drift.

By using a jet of just over an inch in diameter. the jet was able to reach the back of the section of coal that had been exposed when the supports were removed (zone 5 in figure 2) a distance of over 120 ft. the monitor was moved by two sets of hydraulic rams, but if you note where the operator is standing at the back of the machine, this is some 40-ft from the opening and the mining operation itself is not visible.

Figure 3. A monitor in operation at Sparwood. Note the short length of the barrel, which would still produce a high-quality jet, since flow straighteners were used in the barrel, placed directly behind the nozzle.

The operator uses the rams to move the nozzle in an oscillatory path, and listens to the sounds of the jet as it strikes the coal. The sound is quite distinctly different when the jet is hitting coal, as opposed to striking roof rock or shooting into the open space of the drift updip. (I was told this, not having that experience, though I have found similar changes in sound useful in other applications that I will discuss from time to time). It takes, apparently, a couple of days for an operator to be able to consistently detect and use the sound differences to be able to effectively mine with the monitor.

Figure 4. Operator at the Sparwood mine, standing at the back of the machine, and beside the flume.

The way in which the coal broke under the jet attack was only controlled by the operator to a limited extent, so that there can be a significant volume of large coal surviving into the lower entry for collection, and flume transport needed a smaller size distribution. For this reason the coal company installed a coal breaker at the entry to the flume so that the water carried the coal lumps through the breaker, and only then did they enter the flume (Figure 4).

At the time that I visited the site the slurry was higher than shown in the above figure, with coal overlying parts of the back of the breaker. To make it easier to operate the breaker, while keeping the operator safe behind the roof supports, a second small monitor was set by the operator which could be used to clear off the machine from time to time.

The machine was operated by two individuals and over the course of ten years averaged a production of over 3,000 tons a shift. It was also for many years, the safest mine in Canada. To put that production in perspective, in those years an average section in the underground mines in Illinois, running a continuous mining machine, might average about 700 tons a shift, and would need about 14 men to achieve that target. (Production rates have since risen considerably as automation and remote control have reduced the number of folk needed, while higher-powered machines now produce greater coal volumes faster.)

Yet the range of seams where this type of mining can succeed is limited, particularly in the United States, and in coal seams that do not dip as steeply it becomes more difficult to control the particle and water spread as it leaves the impact region.

I’ll talk about a specific way that one can, on occasion, change that, in the next post.

Saturday, May 31, 2014

Monday, May 26, 2014

Tech Talk - China, Russia and East Siberian natural gas

The recent agreement between Russia and China for the sale of some 38 billion cu m of natural gas a year for 30 years, at a reported price of $400 billion ends a long-going negotiation between the two countries over the price of that supply. (Which works out at roughly $10 a thousand cubic feet, just over double current US prices). The price apparently includes some $25 billion to help with construction of the pipelines that will start feeding gas into the Chinese networks within four years. It is less than the price of LNG in the Pacific, and thus will likely lead to market adjustments for that product.

Figure 1. Potential interconnections to bring Russian gas into China (Washington Post )

It is equally of interest to see where the other ends of the potential pipelines lie, since this locates the natural gas fields that will be used to provide the supply. Looking at the distribution of pipelines and fields, the current preponderance of connections into Europe is hard to miss, at the same time as is the large gap in development in the Eastern side of the country.

Figure 2. Natural gas basins in Russia (Oil Peak )

Thus while the potential connection from Urumqi to Gorno-Altaisk allows the Chinese pipeline into a feed from the network that supplies Europe, that market is not going to go away. Yet the two towns are just 560 miles apart and the connection has been known as the Altai project, or Western connection, since it was first planned over 10 years ago, extending a new pipe up towards Yamal and the basins that feed Europe.

Figure 3. The Altai pipeline project (Gazprom )

Developments that reach up into Eastern Siberia, above Lake Baykal and Mongolia into the fields of Kovyktinskoe and Chayandinskoye through the “Power of Siberia” pipeline will allow gas from those fields to also feed Western China.

Figure 4. The connecting fields and pipelines for natural gas from Eastern Siberia (Gazprom )

The gas fields will feed into gas production facilities in Irkutsk and Yakutsk with oil production scheduled to start from Chayandinskoye this year, and natural gas production to follow by 2017. The field is expected to yield 25 billion cu m of natural gas and 1.5 million tons of oil a year at full production, and is estimated to hold 1.2 trillion cu m of natural gas. Kovyktinskoe was licensed to Gazprom in 2011 for exploration and production and is estimated to hold natural gas reserves of 1.5 trillion cu m. Smaller local fields at Bratsk and Chikanskoye have been developed since 2007, with the gas being used locally to supply the region.

Figure 5. Developing natural gas fields in Eastern Siberia (Gazprom )

These two fields alone therefore seem capable of meeting the current sales volume that is to be needed for China, given that the time to delivery is some four years, and both fields are anticipated to be on line, with the gas production facilities, within three years.

Pipeline construction is already underway. The “Power of Siberia” will initially connect into Vladivostock, taking the natural gas to the higher demand industrial Eastern China, but likely the additional funding that China is now providing will also help the Westward expansion to the Western gateway.

Figure 6. The Power of Siberia natural gas pipeline as planned. (Gazprom )

The natural gas pipeline is being routed along with the East Siberia – Pacific Ocean (ESPO) oil pipeline to simplify logistics, the second section of which was opened by President Putin at the end of 2012, a year ahead of schedule. The two sections will have a capacity of handling 80 million tons of oil a year (roughly 1.6 mbd) as supplies increase from the different fields to achieve that target. (The largest current contributor is the Vankor field producing slightly more than 500 kbd).

Yorubcheno-Tokhomskoye is expected to come on line in 2017, reaching full production of around 100 kbd by 2019, as the field develops the natural gas associated with the field will also be brought into the network.

There is anticipated to somewhere around 60 trillion cu. m of natural gas in Eastern Siberia (about 23% of the Russian reserve in 2009) and as this is only now being developed and the infrastructure put in place, it can be expected to last for some considerable time.

So far I have not mentioned the reserves that are now on line at Sakhalin Island. Gazprom built the Sakhalin–Khabarovsk–Vladivostok pipeline in 2011and this carries the natural gas down to Vladivostok, and thence largely into China and other Asian markets. The island also has an LNG facility which supplies that fuel to Japan and North Korea.

Figure 7. Natural gas pipeline from Sakhalin Island (Gazprom )

The pipeline is intended to carry up to 30 bcm per year of natural gas from Sakhalin fields, particularly those offshore.

Given the size of the fields that are thus available to Russia and that will feed into pipelines that will be in place at the time called for in the new agreement it is clear that the new market will not likely require any input from the fields that are currently supplying Europe and other markets.

As industries switch out of coal and into natural gas, however, a change driven partly by environmental and partly by cost considerations, so the demand for natural gas may potentially increase significantly. (As a minor indication of this the primary fossil fuel at the university in town is now natural gas and the coal fired plant just closed). There is less capacity to store natural gas than other fuels, which can raise some concerns over available supply in particularly cold days of the year. Such factors may change the situation somewhat, but realistically I would suspect that natural gas will play an increasing role in global fuel supplies for at least another decade.

Figure 1. Potential interconnections to bring Russian gas into China (Washington Post )

It is equally of interest to see where the other ends of the potential pipelines lie, since this locates the natural gas fields that will be used to provide the supply. Looking at the distribution of pipelines and fields, the current preponderance of connections into Europe is hard to miss, at the same time as is the large gap in development in the Eastern side of the country.

Figure 2. Natural gas basins in Russia (Oil Peak )

Thus while the potential connection from Urumqi to Gorno-Altaisk allows the Chinese pipeline into a feed from the network that supplies Europe, that market is not going to go away. Yet the two towns are just 560 miles apart and the connection has been known as the Altai project, or Western connection, since it was first planned over 10 years ago, extending a new pipe up towards Yamal and the basins that feed Europe.

Figure 3. The Altai pipeline project (Gazprom )

Developments that reach up into Eastern Siberia, above Lake Baykal and Mongolia into the fields of Kovyktinskoe and Chayandinskoye through the “Power of Siberia” pipeline will allow gas from those fields to also feed Western China.

Figure 4. The connecting fields and pipelines for natural gas from Eastern Siberia (Gazprom )

The gas fields will feed into gas production facilities in Irkutsk and Yakutsk with oil production scheduled to start from Chayandinskoye this year, and natural gas production to follow by 2017. The field is expected to yield 25 billion cu m of natural gas and 1.5 million tons of oil a year at full production, and is estimated to hold 1.2 trillion cu m of natural gas. Kovyktinskoe was licensed to Gazprom in 2011 for exploration and production and is estimated to hold natural gas reserves of 1.5 trillion cu m. Smaller local fields at Bratsk and Chikanskoye have been developed since 2007, with the gas being used locally to supply the region.

Figure 5. Developing natural gas fields in Eastern Siberia (Gazprom )

These two fields alone therefore seem capable of meeting the current sales volume that is to be needed for China, given that the time to delivery is some four years, and both fields are anticipated to be on line, with the gas production facilities, within three years.

Pipeline construction is already underway. The “Power of Siberia” will initially connect into Vladivostock, taking the natural gas to the higher demand industrial Eastern China, but likely the additional funding that China is now providing will also help the Westward expansion to the Western gateway.

Figure 6. The Power of Siberia natural gas pipeline as planned. (Gazprom )

The natural gas pipeline is being routed along with the East Siberia – Pacific Ocean (ESPO) oil pipeline to simplify logistics, the second section of which was opened by President Putin at the end of 2012, a year ahead of schedule. The two sections will have a capacity of handling 80 million tons of oil a year (roughly 1.6 mbd) as supplies increase from the different fields to achieve that target. (The largest current contributor is the Vankor field producing slightly more than 500 kbd).

Yorubcheno-Tokhomskoye is expected to come on line in 2017, reaching full production of around 100 kbd by 2019, as the field develops the natural gas associated with the field will also be brought into the network.

There is anticipated to somewhere around 60 trillion cu. m of natural gas in Eastern Siberia (about 23% of the Russian reserve in 2009) and as this is only now being developed and the infrastructure put in place, it can be expected to last for some considerable time.

So far I have not mentioned the reserves that are now on line at Sakhalin Island. Gazprom built the Sakhalin–Khabarovsk–Vladivostok pipeline in 2011and this carries the natural gas down to Vladivostok, and thence largely into China and other Asian markets. The island also has an LNG facility which supplies that fuel to Japan and North Korea.

Figure 7. Natural gas pipeline from Sakhalin Island (Gazprom )

The pipeline is intended to carry up to 30 bcm per year of natural gas from Sakhalin fields, particularly those offshore.

Given the size of the fields that are thus available to Russia and that will feed into pipelines that will be in place at the time called for in the new agreement it is clear that the new market will not likely require any input from the fields that are currently supplying Europe and other markets.

As industries switch out of coal and into natural gas, however, a change driven partly by environmental and partly by cost considerations, so the demand for natural gas may potentially increase significantly. (As a minor indication of this the primary fossil fuel at the university in town is now natural gas and the coal fired plant just closed). There is less capacity to store natural gas than other fuels, which can raise some concerns over available supply in particularly cold days of the year. Such factors may change the situation somewhat, but realistically I would suspect that natural gas will play an increasing role in global fuel supplies for at least another decade.

Saturday, May 24, 2014

Waterjetting 21c - collection in Gilsonite and steep seams

Picking up the debris from a waterjetting operation can be a more expensive part of the process than actually removing the material in the first place. This is particularly true where the material no longer has any inherent value, but is sufficiently toxic that it has to be collected and then properly disposed of. On the other hand, in most aspects of mining, it is the inherent value that is contained in that debris that makes the whole process worthwhile, and in this latter case requires that as much of the material be initially collected as possible. This can be difficult where, for example, gold particles are being produced, since these are heavy and naturally rapidly sink through the water to settle onto the floor where, if this is rough, they can then lie is natural traps that make it hard to re-elevate them and move them to a desired collector.

If one is to continue to move the particles there must be some mechanism that will continue to move the particles to the point that they can be collected. The very condition that makes it difficult to manually mine coal from steeply dipping beds also serves to carry coal and other minerals from those veins, once the material is broken free from the solid.

Consider, for example, the early mining of Gilsonite, which is a naturally occurring hydrocarbon found in thin vertical veins in places such as Utah. It is named after one of its first developers, Samuel H. Gilson.

Figure 1. Pieces of Gilsonite (Metroexpand )

The problem with mining this material is that the dust is very explosive, and remote, safer methods were needed to get men away from the mining process. In 1957 the major American company, American Gilsonite, turned to the use of hydraulic mining. At first the seam was mined using a series of horizontal lifts, with the washed out material and water being collected in drifts that carried it to a pumping station. However, because of the vertical seam, it was easier to used a drill, with lateral jets so that the rotating waterjets mined and flushed the material down into underlying drifts, where it could be collected.

Figure 2. Method for Mining Gilsonite.

By moving the mining tool along the vein the material could be mined out, without miners at the working face, and without the risks of explosion from the conventional mechanical mining methods.

A recent blimp trip over the Bonanza mine shows the results from years of the mining process, as the seam has been removed.

Figure 3. Mined out seam of Gilsonite at Bonanza, Utah. (J.S. and S.W. Aber)

More recently the mine has returned to a mechanical method for mining the material since the customer wanted a dry, rather than a wet product, and, with demand for the material rising, hopefully they will continue to operate safely – the material is now airlifted to the surface. Mining has been restricted to the top 500-ft of the vein.

The hydraulic mining process demonstrated here shows some of the advantages of the use of waterjets in that there are no workers in the mining area, and that the tool is able to remove the mineral without generating the sparks and explosive dust clouds that can be a danger otherwise.

Figure 4. German coal seam side view, showing thickness and angle of slope. (Benedum, W., Harzer, H., and Maurer, H., "The Development and Performance of two Hydromechanical Large Scale workings in the West German Coal Mining Industry," paper J2, Proc. 2nd Int. Symp. Jet Cutting Tech., BHRA.)

Coal mining has some of the same problems, and in Germany the idea was tried (in a slightly modified version) as a way of mining coal. Rather than operate from a drilling rig at the surface, holes were drilled along a very steeply dipping seam. The process was in two parts, evaluating whether it was better to start at the bottom and drill up, or to start at the top and drill down.

Figure 5. Methods tested for bore and mine coal recovery. (Benedum, W., Harzer, H., and Maurer, H., ibid.)

The method where the drill goes down, and then reams back up turns out to be the better approach. The reason for this is that the coal breaks out along natural planes, and these can produce coal pieces that are large enough to block the drilled hole through which all the material must pass, when drilling upwards. This is not a problem when drilling down, since the coal is falling through a much larger space (the mined out volume). This makes it a little more difficult to recover, since it is not confined where it falls into the lower drift. But, by adding a small monitor in the second drift, the broken coal can be lifted back into a slurry that can then be channeled into a flume, and carried away from the working area.

The process was effective, in that it showed that the coal could be mined from one drift to the next, using the method, but it was difficult, because of the varying conditions of the seam over its length, to make the connecting drill holes at an economic speed, and thus to mine the coal at an economic rate.

Figure 6. Looking down to the lower drift from the upper, after mining, with all the coal removed. (Benedum et al ibid)

Note that in the above picture there is little roof collapse into the mined out cavity. This is either beneficial (since it allows all the coal to be removed) or it can be a disadvantage. Other than the safety factor of having a roof hang up until a very large area collapses at one time (where the air blast can do considerable damage), a continual roof collapse as the coal is mined can provide confinement for the water and, hopefully, enough restriction that the water will carry the coal to a collection point.

This was the idea behind the JPL coal mining worm that they proposed some years ago:

Figure 7. The JPL concept for a horizontal jet mining system (Miller, C.G., and Stephens, J.B., Coal Worm: A Remote Coal Extraction Concept, JPL Report 5010-7, December, 22, 1976, Jet Propulsion Laboratory, Pasadena, CA.)

Unfortunately when a coal mine roof collapse occurs the rock breaks into relatively large pieces so that the water can flow away through the pile, without being confined sufficiently to provide the needed motive force to move the coal to the collection point. For that, the system would still need a steeply dipping bed, and I’ll talk more of this and debris collection in future posts.

If one is to continue to move the particles there must be some mechanism that will continue to move the particles to the point that they can be collected. The very condition that makes it difficult to manually mine coal from steeply dipping beds also serves to carry coal and other minerals from those veins, once the material is broken free from the solid.

Consider, for example, the early mining of Gilsonite, which is a naturally occurring hydrocarbon found in thin vertical veins in places such as Utah. It is named after one of its first developers, Samuel H. Gilson.

Figure 1. Pieces of Gilsonite (Metroexpand )

The problem with mining this material is that the dust is very explosive, and remote, safer methods were needed to get men away from the mining process. In 1957 the major American company, American Gilsonite, turned to the use of hydraulic mining. At first the seam was mined using a series of horizontal lifts, with the washed out material and water being collected in drifts that carried it to a pumping station. However, because of the vertical seam, it was easier to used a drill, with lateral jets so that the rotating waterjets mined and flushed the material down into underlying drifts, where it could be collected.

Figure 2. Method for Mining Gilsonite.

By moving the mining tool along the vein the material could be mined out, without miners at the working face, and without the risks of explosion from the conventional mechanical mining methods.

A recent blimp trip over the Bonanza mine shows the results from years of the mining process, as the seam has been removed.

Figure 3. Mined out seam of Gilsonite at Bonanza, Utah. (J.S. and S.W. Aber)

More recently the mine has returned to a mechanical method for mining the material since the customer wanted a dry, rather than a wet product, and, with demand for the material rising, hopefully they will continue to operate safely – the material is now airlifted to the surface. Mining has been restricted to the top 500-ft of the vein.

The hydraulic mining process demonstrated here shows some of the advantages of the use of waterjets in that there are no workers in the mining area, and that the tool is able to remove the mineral without generating the sparks and explosive dust clouds that can be a danger otherwise.

Figure 4. German coal seam side view, showing thickness and angle of slope. (Benedum, W., Harzer, H., and Maurer, H., "The Development and Performance of two Hydromechanical Large Scale workings in the West German Coal Mining Industry," paper J2, Proc. 2nd Int. Symp. Jet Cutting Tech., BHRA.)

Coal mining has some of the same problems, and in Germany the idea was tried (in a slightly modified version) as a way of mining coal. Rather than operate from a drilling rig at the surface, holes were drilled along a very steeply dipping seam. The process was in two parts, evaluating whether it was better to start at the bottom and drill up, or to start at the top and drill down.

Figure 5. Methods tested for bore and mine coal recovery. (Benedum, W., Harzer, H., and Maurer, H., ibid.)

The method where the drill goes down, and then reams back up turns out to be the better approach. The reason for this is that the coal breaks out along natural planes, and these can produce coal pieces that are large enough to block the drilled hole through which all the material must pass, when drilling upwards. This is not a problem when drilling down, since the coal is falling through a much larger space (the mined out volume). This makes it a little more difficult to recover, since it is not confined where it falls into the lower drift. But, by adding a small monitor in the second drift, the broken coal can be lifted back into a slurry that can then be channeled into a flume, and carried away from the working area.

The process was effective, in that it showed that the coal could be mined from one drift to the next, using the method, but it was difficult, because of the varying conditions of the seam over its length, to make the connecting drill holes at an economic speed, and thus to mine the coal at an economic rate.

Figure 6. Looking down to the lower drift from the upper, after mining, with all the coal removed. (Benedum et al ibid)

Note that in the above picture there is little roof collapse into the mined out cavity. This is either beneficial (since it allows all the coal to be removed) or it can be a disadvantage. Other than the safety factor of having a roof hang up until a very large area collapses at one time (where the air blast can do considerable damage), a continual roof collapse as the coal is mined can provide confinement for the water and, hopefully, enough restriction that the water will carry the coal to a collection point.

This was the idea behind the JPL coal mining worm that they proposed some years ago:

Figure 7. The JPL concept for a horizontal jet mining system (Miller, C.G., and Stephens, J.B., Coal Worm: A Remote Coal Extraction Concept, JPL Report 5010-7, December, 22, 1976, Jet Propulsion Laboratory, Pasadena, CA.)

Unfortunately when a coal mine roof collapse occurs the rock breaks into relatively large pieces so that the water can flow away through the pile, without being confined sufficiently to provide the needed motive force to move the coal to the collection point. For that, the system would still need a steeply dipping bed, and I’ll talk more of this and debris collection in future posts.

Monday, May 19, 2014

Tech Talk - Closing a coal-fired power plant

Much is made of large schemes to alter the way in which energy is produced in the United States. Large scale wind farms, and great arrays of solar panels attract large interest and funding, yet it is often in the smaller projects, from the individual solar panels to the change in energy sources for individual factories, or in this case a university, that there is at least as much progress, though with less fanfare.

I wrote, some eighteen months ago about the geothermal plans at Missouri University of Science and Technology (MS&T) previously the University of Missouri-Rolla and my academic home for 42 years. At that time the campus was beginning a process that would see the different parking lots and other open areas around campus disrupted while a series of vertical wells and horizontal pipes was laid beneath the ground, prior to its restoration.

Figure 1. The MS&T Geothermal plan, showing the zoning of the wells and the connection pipe network.

Time has moved on since the initial plans were set in place, the trenches have been dug:

Figure 2. Geothermal trenches on campus, with walkways re-routed around them

Within the lots wells were then drilled roughly 430 ft deep, through which the system fluid will flow, and as these were drilled they were lined and connected by a secondary network.

Figure 3. Drilling the wells in the parking lots at the top right of Figure 1.

The network of wells is connected through plastic pipes that carry the water out to the wells, down and back up and then return to the central heat exchanger systems of the different circuits.

Figure 4. The heat exchange between the water and the ground (inhabitant )

Figure 5. The initial connections to the wells

Larger pipes are required to carry the water to and from the different fields to the processing plants where it is used to heat/chill water in a secondary circuit that is then distributed (depending on season to either warm or cool) through the network to the campus buildings.

Figure 6. The main pipe connections.

The parking lots have since been regraded, tarmac applied, and have, for some time been functioning as before.

Now the project is entering into the final days of installation, as a significant milestone has been reached. This week the coal and wood fired boiler #5 will shut down and all steam production at the campus power plant will permanently cease. Chillers are now operating for the summer to cool the buildings served by three of the regional plantsm which covers most of the air conditioning needs of the campus, and heat is being sent to six of the campus buildings.

Given the age, and change in the nature of the heating and air conditioning service to the buildings some still remain to have their systems upgraded, but most will now be completed while the students are away this summer.

Estimates of the savings that this will bring to the campus are in various forms. The coal and wood that have provided the energy source in the past will no longer be needed (and in time the plant will be removed). As well as the plant itself this will also free up the space where the coal was stored, and will improve the local aesthetic considerably along that side of the campus.

Figure 7. The campus power plant

The change in fuel will also see the overall amount of fuel required reduced, and it is anticipated that the energy use will be cut by 50%. Carbon dioxide emissions will be dropped by 25,000 tons a year (the system will still use significant amounts of natural gas) and water use will be cut by eight million gallons a year.

It is anticipated that the $32 million project will initially yield the campus a saving of around $1 million a year which will rise to more than $3 million a year as energy costs increase, while the system should not need significant maintenance for decades. There is a video of the project here). When completed, sometime next year the system will be serving 15 buildings with around a million square feet of floor space.

As the Missouri system was beginning, the initial phase of a similar system at Ball State was being completed . This will ultimately supply around 5.5 million square feet of campus space, and is expected to yield some $2 million a year in energy cost savings. Following the successful completion of Phase 1 of that project in March 2012, the Phase 2 project, requiring an additional 1,000 boreholes, was started in June of 2013, and is expected to be completed by some time next year. The four coal fired boilers at the plant (which consumed some 36,000 tons of coal a year,) were shut down in March of this year. Power will continue to be supplied from three natural gas boilers on campus. The $80 million project will have drilled a total of around 3,600 wells at the time of completion of Phase 2.

Oregon Tech has a 1.75 MW geothermal power plant, which combined with a solar electric array of panels on a 9-acre site off campus to produce most of the power needs of the campus. The dedication ceremony was on April 18th of this year. It is expected that the plant, which operates on a more conventional use of high-temperature water from the underlying host rock, will save the campus around $400,000 a year in energy. Water is brought up from 5,300 ft below the surface at a temperature of 200 degrees F, and used to spin two turbines, and as source of building heat, before being re-injected.

As the dates suggest this is a very new venture for universities and, as yet, there are not a lot of players in the game. Yet if the savings pan out to be at the level or greater than currently estimated it may well be more popular in the future as overall energy costs continue to rise. (Although in the short term natural gas prices may well rise a little, while coal prices are expected to fall a little).

I wrote, some eighteen months ago about the geothermal plans at Missouri University of Science and Technology (MS&T) previously the University of Missouri-Rolla and my academic home for 42 years. At that time the campus was beginning a process that would see the different parking lots and other open areas around campus disrupted while a series of vertical wells and horizontal pipes was laid beneath the ground, prior to its restoration.

Figure 1. The MS&T Geothermal plan, showing the zoning of the wells and the connection pipe network.

Time has moved on since the initial plans were set in place, the trenches have been dug:

Figure 2. Geothermal trenches on campus, with walkways re-routed around them

Within the lots wells were then drilled roughly 430 ft deep, through which the system fluid will flow, and as these were drilled they were lined and connected by a secondary network.

Figure 3. Drilling the wells in the parking lots at the top right of Figure 1.

The network of wells is connected through plastic pipes that carry the water out to the wells, down and back up and then return to the central heat exchanger systems of the different circuits.

Figure 4. The heat exchange between the water and the ground (inhabitant )

Figure 5. The initial connections to the wells

Larger pipes are required to carry the water to and from the different fields to the processing plants where it is used to heat/chill water in a secondary circuit that is then distributed (depending on season to either warm or cool) through the network to the campus buildings.

Figure 6. The main pipe connections.

The parking lots have since been regraded, tarmac applied, and have, for some time been functioning as before.

Now the project is entering into the final days of installation, as a significant milestone has been reached. This week the coal and wood fired boiler #5 will shut down and all steam production at the campus power plant will permanently cease. Chillers are now operating for the summer to cool the buildings served by three of the regional plantsm which covers most of the air conditioning needs of the campus, and heat is being sent to six of the campus buildings.

Given the age, and change in the nature of the heating and air conditioning service to the buildings some still remain to have their systems upgraded, but most will now be completed while the students are away this summer.

Estimates of the savings that this will bring to the campus are in various forms. The coal and wood that have provided the energy source in the past will no longer be needed (and in time the plant will be removed). As well as the plant itself this will also free up the space where the coal was stored, and will improve the local aesthetic considerably along that side of the campus.

Figure 7. The campus power plant

The change in fuel will also see the overall amount of fuel required reduced, and it is anticipated that the energy use will be cut by 50%. Carbon dioxide emissions will be dropped by 25,000 tons a year (the system will still use significant amounts of natural gas) and water use will be cut by eight million gallons a year.

It is anticipated that the $32 million project will initially yield the campus a saving of around $1 million a year which will rise to more than $3 million a year as energy costs increase, while the system should not need significant maintenance for decades. There is a video of the project here). When completed, sometime next year the system will be serving 15 buildings with around a million square feet of floor space.

As the Missouri system was beginning, the initial phase of a similar system at Ball State was being completed . This will ultimately supply around 5.5 million square feet of campus space, and is expected to yield some $2 million a year in energy cost savings. Following the successful completion of Phase 1 of that project in March 2012, the Phase 2 project, requiring an additional 1,000 boreholes, was started in June of 2013, and is expected to be completed by some time next year. The four coal fired boilers at the plant (which consumed some 36,000 tons of coal a year,) were shut down in March of this year. Power will continue to be supplied from three natural gas boilers on campus. The $80 million project will have drilled a total of around 3,600 wells at the time of completion of Phase 2.

Oregon Tech has a 1.75 MW geothermal power plant, which combined with a solar electric array of panels on a 9-acre site off campus to produce most of the power needs of the campus. The dedication ceremony was on April 18th of this year. It is expected that the plant, which operates on a more conventional use of high-temperature water from the underlying host rock, will save the campus around $400,000 a year in energy. Water is brought up from 5,300 ft below the surface at a temperature of 200 degrees F, and used to spin two turbines, and as source of building heat, before being re-injected.

As the dates suggest this is a very new venture for universities and, as yet, there are not a lot of players in the game. Yet if the savings pan out to be at the level or greater than currently estimated it may well be more popular in the future as overall energy costs continue to rise. (Although in the short term natural gas prices may well rise a little, while coal prices are expected to fall a little).

Saturday, May 17, 2014

Waterjetting 21b - collecting debris, or mined product

You don’t have to operate a water jet lance for any time before realizing that the rebounding water, and the debris from the operation can’t be ignored. On the other hand, after they fall to the floor they rapidly lose their energy and without some additional input will lie in the most inconvenient places until moved. Protection from the rebound is a critical part of the protective clothing and equipment that the operator wears (including side shields for the eye protection) but the collection and removal of the spent material is also critical to good operations, and in uses such as mining it is needed to carry the material to a point where it can be processed.

While this was fairly obvious to those who used water in earlier times to wash out soil and minerals and carry them down to flumes and separation devices, it was not always immediately obvious to those who experimented with the use of larger jets for underground mining. There are two critical velocities involved, once the particles are removed from the surface, these are the settling velocity and the suspension velocities of the particles. Essentially these are the speeds at which the transporting water is travelling that prevents, or encourages, the particles to settle out. This is an important part of drilling horizontal holes, where the drill cuttings can settle in the long hole hehind the drill, and can both stop the drill from moving forwards and also trap it when it tries to retract (personal experience).

Figure 1. Settling velocities (after VCCS)

Because of the wide range of particles that are mined by a jet, it is sometimes suggested that flow velocities in flumes remain above 40 ft/sec. It becomes a lot more difficult to get particles back into suspension after they have settled out.

Because water and debris are dispersed around the impact point after jet impact and because the amount of water needed to keep the particles suspended and moving has to be high, this often means that the geometry of the excavation has to be tailored to capture and confine the water in a narrow space with the mined product.

The National Coal Board carried out early experiments in coal mining in Wales at Trelewis Drift. (Jenkins R.W. “hydraulic Mining – The NCB Installation at Trelewis Drift” MSc Thesis, University of Wales, 1961).

Figure 2. Early NCB remotely operated monitor (after Jenkins ibid).

The 5-ft 6-inch thick seam dipped at roughly 6 degrees, and the monitor was used initially to drive the drift, and then to slab off coal from the pillars on either side, and then to mine along the face of a pillar, driving coal from one drift to the next adjacent, as the drift was retreated.

Part of the problem that arose was that the coal broke off in pieces that were up to 2-ft thick, and once these fell to the floor they became more difficult to recover, particularly where they were scattered (and this was the reason that the monitor was being operated remotely since the debris was reaching the miners). (Jet pressure was around 1,000 psi). The mine was naturally very wet (over the waders of some miners) and production did not exceed 45 tons a shift, even though the costs at the time were around 50-pence per ton in 1963. The conclusion was that the slope of the seam was not adequate to help enough with coal transport and the experiments were terminated.

This is in contrast to work elsewhere (the British trials had been commissioned after Russian hydraulic mining trials had been reported as successful). But the Russian work was carried out in the Donets coal basin, where the seams are much steeper, and more difficult to mine conventionally.

V.S. Muchnick wrote his dissertation on hydraulic coal mining in 1935, describing these early trials. While it was difficult to manually work in the steep seams, setting up a simple monitor that would wash away the coal, which would then fall under gravity to the drift tunnel beneath the mining operation was much more successful.

Figure 3. Early Russian Monitor (RGM-1)

Because of the Second World War hydraulic mining did not get its start until 1952 at the Tyrganskii-Uklony mine in the Kuznetsk Basin. Production in the hydraulic sections was anticipated to be 500 tons.shift, but by the end of the first year it had already exceeded 600 tons, more than twice conventional mining production. In the early operations the coal was weakened by blasting, but by 1957 jet pressures were raised sufficiently that this was no longer needed.

Figure 4. Showing the major Russian coal basins (Gazprom )

By 1979 there were nine major hydraulic mines in the Soviet Union with an annual production of over 8.9 million tonnes. As the mining operations expanded, so the monitors were increasingly operated remotely using hydraulic cylinders to direct the jets at the coal. At pressures of 1,500 psi the monitors could mine over 50 tonnes an hour, using around 650 gpm of water. (This was later doubled).

In almost all these operations the mine is worked in retreat, first driving the drifts to the back of the section, and then mining back, allowing the coal either to fall into the drift, where the water volume is sufficient to carry it into the flume, or pushing it down to the underlying drift, where it can similarly be collected.

Figure 5. GMDTs-3M monitor used in the Soviet Union

The mining pattern changed with the thickness of the coal, and with the steepness of the slopes at which the seams ran, although the access drifts were run more up dip, while the mining drifts were at a shallower angle closer to horizontal, so as to make working conditions easier, and to more effectively remove most of the coal from the section. In this way the coal collapsed under gravity down to the drift, where the water would float it into the flume. ( A barrier across the drift would confine the water and coal and act as a feed mechanism).

Figure 6. Method of mining in Soviet hydraulic mines in gently dipping seams of average thickness.

I will discuss the expansion of the technology around the world in later posts.

While this was fairly obvious to those who used water in earlier times to wash out soil and minerals and carry them down to flumes and separation devices, it was not always immediately obvious to those who experimented with the use of larger jets for underground mining. There are two critical velocities involved, once the particles are removed from the surface, these are the settling velocity and the suspension velocities of the particles. Essentially these are the speeds at which the transporting water is travelling that prevents, or encourages, the particles to settle out. This is an important part of drilling horizontal holes, where the drill cuttings can settle in the long hole hehind the drill, and can both stop the drill from moving forwards and also trap it when it tries to retract (personal experience).

Figure 1. Settling velocities (after VCCS)

Because of the wide range of particles that are mined by a jet, it is sometimes suggested that flow velocities in flumes remain above 40 ft/sec. It becomes a lot more difficult to get particles back into suspension after they have settled out.

Because water and debris are dispersed around the impact point after jet impact and because the amount of water needed to keep the particles suspended and moving has to be high, this often means that the geometry of the excavation has to be tailored to capture and confine the water in a narrow space with the mined product.

The National Coal Board carried out early experiments in coal mining in Wales at Trelewis Drift. (Jenkins R.W. “hydraulic Mining – The NCB Installation at Trelewis Drift” MSc Thesis, University of Wales, 1961).

Figure 2. Early NCB remotely operated monitor (after Jenkins ibid).

The 5-ft 6-inch thick seam dipped at roughly 6 degrees, and the monitor was used initially to drive the drift, and then to slab off coal from the pillars on either side, and then to mine along the face of a pillar, driving coal from one drift to the next adjacent, as the drift was retreated.

Part of the problem that arose was that the coal broke off in pieces that were up to 2-ft thick, and once these fell to the floor they became more difficult to recover, particularly where they were scattered (and this was the reason that the monitor was being operated remotely since the debris was reaching the miners). (Jet pressure was around 1,000 psi). The mine was naturally very wet (over the waders of some miners) and production did not exceed 45 tons a shift, even though the costs at the time were around 50-pence per ton in 1963. The conclusion was that the slope of the seam was not adequate to help enough with coal transport and the experiments were terminated.

This is in contrast to work elsewhere (the British trials had been commissioned after Russian hydraulic mining trials had been reported as successful). But the Russian work was carried out in the Donets coal basin, where the seams are much steeper, and more difficult to mine conventionally.

V.S. Muchnick wrote his dissertation on hydraulic coal mining in 1935, describing these early trials. While it was difficult to manually work in the steep seams, setting up a simple monitor that would wash away the coal, which would then fall under gravity to the drift tunnel beneath the mining operation was much more successful.

Figure 3. Early Russian Monitor (RGM-1)

Because of the Second World War hydraulic mining did not get its start until 1952 at the Tyrganskii-Uklony mine in the Kuznetsk Basin. Production in the hydraulic sections was anticipated to be 500 tons.shift, but by the end of the first year it had already exceeded 600 tons, more than twice conventional mining production. In the early operations the coal was weakened by blasting, but by 1957 jet pressures were raised sufficiently that this was no longer needed.

Figure 4. Showing the major Russian coal basins (Gazprom )

By 1979 there were nine major hydraulic mines in the Soviet Union with an annual production of over 8.9 million tonnes. As the mining operations expanded, so the monitors were increasingly operated remotely using hydraulic cylinders to direct the jets at the coal. At pressures of 1,500 psi the monitors could mine over 50 tonnes an hour, using around 650 gpm of water. (This was later doubled).

In almost all these operations the mine is worked in retreat, first driving the drifts to the back of the section, and then mining back, allowing the coal either to fall into the drift, where the water volume is sufficient to carry it into the flume, or pushing it down to the underlying drift, where it can similarly be collected.

Figure 5. GMDTs-3M monitor used in the Soviet Union

The mining pattern changed with the thickness of the coal, and with the steepness of the slopes at which the seams ran, although the access drifts were run more up dip, while the mining drifts were at a shallower angle closer to horizontal, so as to make working conditions easier, and to more effectively remove most of the coal from the section. In this way the coal collapsed under gravity down to the drift, where the water would float it into the flume. ( A barrier across the drift would confine the water and coal and act as a feed mechanism).

Figure 6. Method of mining in Soviet hydraulic mines in gently dipping seams of average thickness.

I will discuss the expansion of the technology around the world in later posts.

Sunday, May 11, 2014

Tech Talk - without Cellulosic Ethanol where will transportation fuel come from?

There are some ominous signs that we are beginning to reach a point where it is less economic to look for and develop new supplies of oil, as costs rise, return on investment becomes less certain, and alternate opportunities exist for the funds that promise a better return with a lower initial investment. The problem, of course, that this generates is that as existing fields decline, so the fields that remain are likely to be smaller and more difficult (and thus expensive) to develop. To meet the need, therefore, exploration investment needs to increase, rather than decline, since the need is to find an increasing number of the smaller fields. Without those searches, then future supply will increasingly be unable to meet the growth in demand.

Further, given the time that is required to find new fields, develop them and then connect into a distribution network that carries the oil to refineries and the customer, without the knowledge of what is going to be needed, the crisis of under supply will approach not only more rapidly but also with less flexibility in being able to remediate the shortages when they start developing.

A large part of the problem lies in the way that oil is used. With much of it being refined into transportation fuels – in the USA some 70% - there is little in the short run that can be used to replace it.

Figure 1. Percentage uses of petroleum products in different sectors of the USA (Institute for Energy Research )

Since we are unlikely to see much change in power sources for vehicles in the next couple of years, as the oil shortage begins to bite there is insufficient flexibility in the system to offer an immediate alternative that will be viable. While corn ethanol has provided (at some cost) less than a million barrels a day it has reached an apparent plateau of production that is unlikely to change, given the alternate demand for the corn.

Figure 2. Ethanol Production in the United States (EIA) (Note: A billion gallons a year is roughly 65 kbd).

Cellulosic ethanol remains an unfulfilled promise, back in 2010 there was already some concern that it would meet even the initial targets, as time has worn on these seem increasingly out of touch.

Figure 3. Projected needs for cellulosic ethanol to meet projected national needs by 2030. (Bloomberg Biomass Magazine )

More recently Robert Rapier has noted that KiOR, one of the companies that Vinod Khosla founded and then took public as a promised source for this ethanol, is failing to live up to its promises, and may likely soon be bankrupt. It began shipments in 2013 from its Columbus, MS plant but of only nominal quantities of fuel relative to the future need. Shortly thereafter the plant shut down through the first quarter of this year, needing additional funds to improve operational efficiency.

Share prices that started at $15 have now dropped to $0.64, having recently visited $0.59 a share. Investments to make those changes may only come for a limited time, perhaps only through August, from Mr. Khosla. But the company has to pay back the $75 million it borrowed from Mississippi – with the next $1.8 million payment due June 30th, and there don’t appear to be other investors waiting in the wings. The state will get the assets should the company fold.

Sadly this is another exemplary case of a number of firms who promised much in this field, but have so far delivered relatively little, although there are several new plants coming on stream this year. The EPA has suggested that the production target for this year be lowered from 6 billion liters to 64 million liters – a significant cut, and one indicative of the likely difficulties in finding alternate sources to petroleum based products needed for the transportation industry when oil becomes less available.

Figure 4. Status of the Cellulosic ethanol production plants planned to be in operation by the end of this year (Nature )

The INEOS plant in Florida began production last July but then shut down and is looking to achieve stable production this year, after upgrading the facility, which will have a capacity of 8 million gallons a year. Not much against the millions of barrels a day that may be needed, but the company has the advantage that it is using local municipal waste and also providing power to the community – which provide other gains to their operations.

The Hirsch Report was published in February 2005. In that report the authors noted that it would likely take up to 20-years of concerted effort to produce an alternate source to petroleum based fuels. We are now nearly ten years through this potential period of grace, and the major candidate to provide that alternate resource is so far being found wanting.

The writing on the wall is increasingly discernable, oil companies are cutting back on exploration investment ensuring that future discoveries will likely be smaller in number as well as in size. This will reduce the amount available, requiring an alternate source. Cellulosic ethanol, which has been held up as one answer to the problem, is falling significantly short of the mark needed to make up for possible conventional shortfalls within the next decade.

The question then becomes – what is the alternative? We could look to making oil from coal, peat and other alternate sources as was done in Germany in World War 2 and in South Africa, where SASOL continues to operate. But planning, permitting, building and operating a facility to convert coal is something that will take at least seven years, and require initiatives to make commitments that are currently lacking.

What else is there? Bear in mind that solar and wind energy production largely goes to address the electricity market – which is largely separate from that of the transportation fuels. Thus their development will largely not impact the problem, since electric cars cannot be produced in the quantities that will likely be needed in the time that remains. Bedazzled by the promise of cellulosic ethanol we have failed to properly pursue the alternatives that now look as though they will prove to be needed.

Time is running short, but awareness of the problem is as yet, even less evident. Basking in the transient benefits of increased domestic production, even as turmoil has cut global oil production by an estimated 2.3 mbd, production that won't soon return, there is less inclination to face the issue than there has been in previous Administrations, even though it is now becoming possible that it will be this Administration that first sees the impact.

Further, given the time that is required to find new fields, develop them and then connect into a distribution network that carries the oil to refineries and the customer, without the knowledge of what is going to be needed, the crisis of under supply will approach not only more rapidly but also with less flexibility in being able to remediate the shortages when they start developing.

A large part of the problem lies in the way that oil is used. With much of it being refined into transportation fuels – in the USA some 70% - there is little in the short run that can be used to replace it.

Figure 1. Percentage uses of petroleum products in different sectors of the USA (Institute for Energy Research )

Since we are unlikely to see much change in power sources for vehicles in the next couple of years, as the oil shortage begins to bite there is insufficient flexibility in the system to offer an immediate alternative that will be viable. While corn ethanol has provided (at some cost) less than a million barrels a day it has reached an apparent plateau of production that is unlikely to change, given the alternate demand for the corn.

Figure 2. Ethanol Production in the United States (EIA) (Note: A billion gallons a year is roughly 65 kbd).

Cellulosic ethanol remains an unfulfilled promise, back in 2010 there was already some concern that it would meet even the initial targets, as time has worn on these seem increasingly out of touch.

Figure 3. Projected needs for cellulosic ethanol to meet projected national needs by 2030. (Bloomberg Biomass Magazine )

More recently Robert Rapier has noted that KiOR, one of the companies that Vinod Khosla founded and then took public as a promised source for this ethanol, is failing to live up to its promises, and may likely soon be bankrupt. It began shipments in 2013 from its Columbus, MS plant but of only nominal quantities of fuel relative to the future need. Shortly thereafter the plant shut down through the first quarter of this year, needing additional funds to improve operational efficiency.

Share prices that started at $15 have now dropped to $0.64, having recently visited $0.59 a share. Investments to make those changes may only come for a limited time, perhaps only through August, from Mr. Khosla. But the company has to pay back the $75 million it borrowed from Mississippi – with the next $1.8 million payment due June 30th, and there don’t appear to be other investors waiting in the wings. The state will get the assets should the company fold.

Sadly this is another exemplary case of a number of firms who promised much in this field, but have so far delivered relatively little, although there are several new plants coming on stream this year. The EPA has suggested that the production target for this year be lowered from 6 billion liters to 64 million liters – a significant cut, and one indicative of the likely difficulties in finding alternate sources to petroleum based products needed for the transportation industry when oil becomes less available.

Figure 4. Status of the Cellulosic ethanol production plants planned to be in operation by the end of this year (Nature )

The INEOS plant in Florida began production last July but then shut down and is looking to achieve stable production this year, after upgrading the facility, which will have a capacity of 8 million gallons a year. Not much against the millions of barrels a day that may be needed, but the company has the advantage that it is using local municipal waste and also providing power to the community – which provide other gains to their operations.

The Hirsch Report was published in February 2005. In that report the authors noted that it would likely take up to 20-years of concerted effort to produce an alternate source to petroleum based fuels. We are now nearly ten years through this potential period of grace, and the major candidate to provide that alternate resource is so far being found wanting.

The writing on the wall is increasingly discernable, oil companies are cutting back on exploration investment ensuring that future discoveries will likely be smaller in number as well as in size. This will reduce the amount available, requiring an alternate source. Cellulosic ethanol, which has been held up as one answer to the problem, is falling significantly short of the mark needed to make up for possible conventional shortfalls within the next decade.

The question then becomes – what is the alternative? We could look to making oil from coal, peat and other alternate sources as was done in Germany in World War 2 and in South Africa, where SASOL continues to operate. But planning, permitting, building and operating a facility to convert coal is something that will take at least seven years, and require initiatives to make commitments that are currently lacking.

What else is there? Bear in mind that solar and wind energy production largely goes to address the electricity market – which is largely separate from that of the transportation fuels. Thus their development will largely not impact the problem, since electric cars cannot be produced in the quantities that will likely be needed in the time that remains. Bedazzled by the promise of cellulosic ethanol we have failed to properly pursue the alternatives that now look as though they will prove to be needed.

Time is running short, but awareness of the problem is as yet, even less evident. Basking in the transient benefits of increased domestic production, even as turmoil has cut global oil production by an estimated 2.3 mbd, production that won't soon return, there is less inclination to face the issue than there has been in previous Administrations, even though it is now becoming possible that it will be this Administration that first sees the impact.

Saturday, May 10, 2014

Waterjetting 21a - Of peat, coal and New Zealand

During the historical development of waterjets there was not a lot of change from the time of the Ancient Greeks, who found water flow being used to uncover and move minerals such as gold, and the Northern British miners of the 1800’s who were still using this tool in a form known as “hushing” as a way of helping to get lead ore out of the ground. The use of a directed higher-pressure stream (even though only powered by gravity) through a nozzle, as a way of mining the gold ores of California was the first step in a major change.

In part this was because the higher pressures sped the process up considerably, and in part it was because there was more method in the way that the jets were applied, so that the operators were kept safe and away from the area where the jets were mining, and where the surrounding rock was unstable. This had advantages in other applications.

Consider that peat is a fuel that is still mined and used in various parts of the world. (As a young man I helped my father dig peat in the spring using a shovel, and then carry it back to my Grandma’s house where it would dry over the summer and be burned the following winter.) But many peat bogs are relatively unstable places, so that bringing in heavy equipment is difficult given the soft ground. Modern practice is to cut large drainage channels around the mining area, allow the water to drain out and then mine the dried peat, which is more often these days used in gardening.

However, before such large operational processes were around peat miners had used water jets (along the lines of those used in California) to break out the fibrous material, and then to move the liquefied slurry in pipelines which are easier and lighter on the land than road beds. Back in 1979, for example:

Figure 1. A peat mining operation (the peat is transported away in the pipeline. (SRS Crisafulli)

Given that peat covers about 3% of the world land surface it is sometimes surprising that more has not been made of the resource, although it is physically strenuous to mine manually, and the high water content means that it must be dried before it can be used. This is why the largest market in America has become the garden market where the costs can be more easily absorbed by the market, and modern vacuum mining of the dried material has become the more common modern method of extraction.

Figure 2. Peat distribution around the world (SRS Crisafulli).

The first mention of hydraulic mining of peat came from Prussia, and by 1914 it was used as the primary source of fuel for the Electroperedacha Electric Power Station in Russia. After the war that usage had grown to mining roughly a third of all the peat mined in the Soviet Union. (Yufin A.P Hydromechanization, State Scientific Technical Press of Literature in Mining, Moscow 1965). There was, however, another place where remote mining can have a considerable advantage.

There are many places in the world where coal beds, originally laid down horizontally, have over the course of time been tilted to steep angles. These mines are very difficult to work in, since the steep slopes can be dangerous to workers, and productivity is generally quite slow. It appeared to dawn on mining engineers in both Russia and New Zealand at about the same time, that using water to mine and move the coal might get away from many of the problems of moving men, material and supports to a working face that isn’t that stable or needed for very long. A simple schematic shows the process:

Figure 3. Early New Zealand hydraulic mining operation (New Zealand Ministry of Culture and Heritage.

In the initial operations the coal was first weakened by blasting it with explosive, and as pressures and flow rates were increased this was found to be unnecessary, and the coal could be mined from the sold. Further, although the illustration shows that a man is directing the stream at the coal face, earlier methods had the stream being directed along a face, carrying the coal from one entry to another, where it could be flumed and carried away, by the same water flow.

By a suitable choice of geometry this did not need an operator to guide the jet stream, and so the practice arose back then of firing the face, and turning on the water flow and going home for the evening. When the miners arrived back the following day the coal had been moved down to storage (or in some cases out through a lower adit and out of the mine) and the face was cleaned off. All that was needed was to insert new roof supports in the exposed part of the seam, move the hydraulic channel over to the new face, drill it, and then, at the end of the shift, blast down the coal and go home. I will confess this is a much less strenuous way of mining than the 15 yards length of blasted coal some 6 ft deep that I had to physically move onto a conveyor each day with a shovel and pick (to break up the big lumps and to drive wedges above the props to hold the roof up) back when I was an Indentured Apprentice.

There are a number of different ways in which the coal was mined, with the pattern of extraction changing with the slope of the coal seam, the thickness of the seam and the strength of the overlying rock (since as the jet mining distances grew greater the area mined was no longer supported) and I will discuss some of these in more detail over the next couple of posts or so.

In part this was because the higher pressures sped the process up considerably, and in part it was because there was more method in the way that the jets were applied, so that the operators were kept safe and away from the area where the jets were mining, and where the surrounding rock was unstable. This had advantages in other applications.

Consider that peat is a fuel that is still mined and used in various parts of the world. (As a young man I helped my father dig peat in the spring using a shovel, and then carry it back to my Grandma’s house where it would dry over the summer and be burned the following winter.) But many peat bogs are relatively unstable places, so that bringing in heavy equipment is difficult given the soft ground. Modern practice is to cut large drainage channels around the mining area, allow the water to drain out and then mine the dried peat, which is more often these days used in gardening.

However, before such large operational processes were around peat miners had used water jets (along the lines of those used in California) to break out the fibrous material, and then to move the liquefied slurry in pipelines which are easier and lighter on the land than road beds. Back in 1979, for example:

Western Peat Moss Ltd in Vancouver is currently using hydraulic mining and pumps a peat moss slurry of a concentration varying beteen 0.75 and 1.5% by mass, a distance of 3.65 km in a pipeline 0.3 m in diameter, at a rate of 340 cubic m/hour (1,500 gpm). A similar operation is being used in Alberta by Hood Manufacturing Ltd, for the mining and transport of Peat moss.

Figure 1. A peat mining operation (the peat is transported away in the pipeline. (SRS Crisafulli)

Given that peat covers about 3% of the world land surface it is sometimes surprising that more has not been made of the resource, although it is physically strenuous to mine manually, and the high water content means that it must be dried before it can be used. This is why the largest market in America has become the garden market where the costs can be more easily absorbed by the market, and modern vacuum mining of the dried material has become the more common modern method of extraction.

Figure 2. Peat distribution around the world (SRS Crisafulli).

The first mention of hydraulic mining of peat came from Prussia, and by 1914 it was used as the primary source of fuel for the Electroperedacha Electric Power Station in Russia. After the war that usage had grown to mining roughly a third of all the peat mined in the Soviet Union. (Yufin A.P Hydromechanization, State Scientific Technical Press of Literature in Mining, Moscow 1965). There was, however, another place where remote mining can have a considerable advantage.

There are many places in the world where coal beds, originally laid down horizontally, have over the course of time been tilted to steep angles. These mines are very difficult to work in, since the steep slopes can be dangerous to workers, and productivity is generally quite slow. It appeared to dawn on mining engineers in both Russia and New Zealand at about the same time, that using water to mine and move the coal might get away from many of the problems of moving men, material and supports to a working face that isn’t that stable or needed for very long. A simple schematic shows the process:

Figure 3. Early New Zealand hydraulic mining operation (New Zealand Ministry of Culture and Heritage.

In the initial operations the coal was first weakened by blasting it with explosive, and as pressures and flow rates were increased this was found to be unnecessary, and the coal could be mined from the sold. Further, although the illustration shows that a man is directing the stream at the coal face, earlier methods had the stream being directed along a face, carrying the coal from one entry to another, where it could be flumed and carried away, by the same water flow.

By a suitable choice of geometry this did not need an operator to guide the jet stream, and so the practice arose back then of firing the face, and turning on the water flow and going home for the evening. When the miners arrived back the following day the coal had been moved down to storage (or in some cases out through a lower adit and out of the mine) and the face was cleaned off. All that was needed was to insert new roof supports in the exposed part of the seam, move the hydraulic channel over to the new face, drill it, and then, at the end of the shift, blast down the coal and go home. I will confess this is a much less strenuous way of mining than the 15 yards length of blasted coal some 6 ft deep that I had to physically move onto a conveyor each day with a shovel and pick (to break up the big lumps and to drive wedges above the props to hold the roof up) back when I was an Indentured Apprentice.

There are a number of different ways in which the coal was mined, with the pattern of extraction changing with the slope of the coal seam, the thickness of the seam and the strength of the overlying rock (since as the jet mining distances grew greater the area mined was no longer supported) and I will discuss some of these in more detail over the next couple of posts or so.

The Icelandic Earthquakes are a little stronger

There seems to be an increase in the strength of the quakes that are happening along the southern part of the line, initially focussed on the Reykjanes Ridge, but now apparently spreading further north. Although it looks intense, remember the scale over which the events are happening. And also remember that these indicate some movement, so that those parts next to them that don't move will build up stress that must, ultimately, be relieved.

Figure 1. Earthquakes in Iceland in the 48 hours before May 10,2014 (Icelandic Met Office)

There is no more. . . . .yet

Figure 1. Earthquakes in Iceland in the 48 hours before May 10,2014 (Icelandic Met Office)

There is no more. . . . .yet

Wednesday, May 7, 2014

Tech Talk - Fast destruction and slow reconstruction

Underlying many of the projections of future energy supply that are now being made there are, as mentioned earlier, a lot of assumptions that are beginning to appear more questionable as time passes. Much of the concern has to focus on the instability in the Middle East and North African nations (MENA) that are now increasingly unsettled by civil conflict. While optimism in many reviews anticipates that the turmoil will decline and nations will return to pre-conflict levels or higher, particularly in the case of Iraq, unfortunately this conflicts with much of what we have learned from recent history. Sadly there is also the history of Gazprom, which now also suggests that rosy visions of the future are only that, and what is coming is likely to be much grimmer.

Considering first Libya, once the infrastructure of an oilfield and its links to the outside world, and the operators that run it have been destroyed, seriously damaged or dissuaded from being there, then, particularly where conflict continues over time, restoration of pre-conflict volumes can take more than a decade. Once combatants become embittered by the realities of civil war, so their willingness to subsume the hatreds and other burdens brought on by loss becomes more difficult to engage, and conflict drags on with its continued losses for society. Libya is a sad example of how rapidly production can collapse.

Figure 1. Libyan oil production pre-current conflict (SEPM strata )

The country has now reached as low a rate of daily production (around 240 kbd) as it has seen in recent years.

Figure 2. Recent Libyan oil production (from OPEC MOMR)