Sunday, November 24, 2013

Waterjetting 15c - Surface quality

In the beginning, when the very name of waterjet cutting was, in itself enough to create an interest, the quality of the surface that was left after the jet passed was not a critical factor. The surface was, relative to other techniques, left in a cold condition without the imposition of additional stresses brought about by the cutting process. This, in itself brought some benefits to the use of this new tool, and when melded with the benefit of a continually sharpening blade, meant that there were a wide variety of applications where it had an immediate (in not so quickly recognized) benefit. One of these was in the cutting of food products. Here, where the aesthetic need for a sharp clean-cut surface could be joined with the reduced crushing along the cut line, provided an increased appeal both in immediate and longer-term to the use of a plain waterjet system.

Back in the days when we were all trying to find new ways of using this new tool, I remember colleagues from the National Research Council in Canada commenting about relative trials in cutting peaches. The problem with mechanical cutting of freestone peaches is that the knives occasionally hit the stone, distorting the cutting edge and, over time, making for a ragged cut. In looking for alternatives, the NRC compared laser cutting with that of a high-pressure waterjet system. With the laser there was this strong smell of burning, a relatively wide cut appeared on the surface, but the high water content of the flesh of the peach inhibited further cutting. With the waterjet, in contrast, the cut was cleanly and effectively achieved within the necessary time. The cut was clean, and without the compression of fibers that would, otherwise over time lead to discoloration and customer dislike. More recently this same result has led to the widespread use of waterjets in trimming, for example, the lengths of celery that are found in the grocery sections of many stores.

Cut edge quality is thus an important issue when it comes to selling the benefits of this new tool. But edge quality means different things to different customers. To aircraft manufacturers that we have worked with, being able to cut through half-inch thick titanium with a precision of 0.001 inches over the alignment of the cut was a critical problem. In cutting the walls of the Omnimax Theater under the Gateway Arch in St. Louis we were asked to maintain the wall alignment, over its fifteen-foot depth, within an inch of vertical. (Which turns out to be a precision of 0.005 inches per inch, not that much greater a tolerance than that we provided in the aircraft application). In cutting through the granite to make the Millennium Arch the concern was more to ensure that when the central figure was completely outlined that there would be no protrusion that would stop the two parts of the piece being separated.

In traditional processing, it is common to expect that, after the pieces of an assembly have been separately cut out, that the part edges will be finished separately, before the components are brought together in final assembly. Thus, as an example, after using a cutting device to cut the shapes of different parts of an assembly, secondary finishing is built into the cost and time schedule to allow for this additional step of cleaning up the edges of the parts to remove the cut imperfections that form as a part of conventional cutting.

But, in many cases, the use of an abrasive waterjet system does not require that second step. The quality of the initial surface cut is well within the bounds of precision and accuracy that are required to meet the final assembly part requirements. As a result there is at least one, and often more steps that can be eliminated from the assembly schedule, and the costs for those set against any additional costs that the waterjet cutting costs might have initially brought into the overall picture. In assembly costs time is money, and the elimination of steps in a process can be significantly greater than just those occurred in the process itself. It is an advantage that is not often fully recognized.

Consider, for example, the simple case where two surfaces are to be riveted together. In the older, conventional practice the two parts would be mated one to the other, while a machinist came along and drilled the rivet holes through the two parts. The parts would then be separated while the burrs and machining residue was removed from the two pieces separately, and then they would be relocated and re-aligned, and a riveter would then come along and drive in the rivets to hold the parts together.

In contrast, where an abrasive waterjet is used the tool can cut through both (or more) parts without burring on the edge, leaving holes of high enough edge quality that there is no burring or need for subsequent re-finishing. The rivets can be immediately installed in the appropriate holes, which are already aligned and ready, and two lengthy and costly process steps can be saved.

As a trivial issue, but one of increasing importance as the cost of raw materials increases, the component pieces that are cut from the solid to make the two parts can also be recovered as a single piece, with the opportunity for use in another application, rather than being rendered down into scrap that must first be reconstituted in to a solid piece.

To continue with the analogy (though it is admittedly a bit hard to find a secondary use for metal of this shape) the metal removed from the rivet hole can be recovered in a single piece.

Figure 1. Rivet hole metal removed from a sample as a single piece, compared with the conventional alternative.

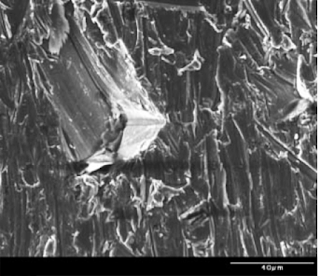

There is, however, one caveat to this discussion, and that relates to surfaces that will be precision welded after cutting. One of the problems that abrasive waterjets can create, is the occasional embedment of the abrasive particles within the cut surface. (Figure 2).

Figure 2. SEM image showing abrasive particles embedded in a surface after cutting. (Dr. Galecki)

Where this is a possible problem then the simple answer, as my colleague Dr. Greg Galecki has demonstrated, is to repeat the cutting path but with a high-pressure waterjet along feeding over the cut surface (at a higher traverse speed). This removed the buried pieces and leaves the surface in the condition required.

Figure 3. SEM image of cleaned surface showing a representative site where the embedded particle has been removed.

Back in the days when we were all trying to find new ways of using this new tool, I remember colleagues from the National Research Council in Canada commenting about relative trials in cutting peaches. The problem with mechanical cutting of freestone peaches is that the knives occasionally hit the stone, distorting the cutting edge and, over time, making for a ragged cut. In looking for alternatives, the NRC compared laser cutting with that of a high-pressure waterjet system. With the laser there was this strong smell of burning, a relatively wide cut appeared on the surface, but the high water content of the flesh of the peach inhibited further cutting. With the waterjet, in contrast, the cut was cleanly and effectively achieved within the necessary time. The cut was clean, and without the compression of fibers that would, otherwise over time lead to discoloration and customer dislike. More recently this same result has led to the widespread use of waterjets in trimming, for example, the lengths of celery that are found in the grocery sections of many stores.

Cut edge quality is thus an important issue when it comes to selling the benefits of this new tool. But edge quality means different things to different customers. To aircraft manufacturers that we have worked with, being able to cut through half-inch thick titanium with a precision of 0.001 inches over the alignment of the cut was a critical problem. In cutting the walls of the Omnimax Theater under the Gateway Arch in St. Louis we were asked to maintain the wall alignment, over its fifteen-foot depth, within an inch of vertical. (Which turns out to be a precision of 0.005 inches per inch, not that much greater a tolerance than that we provided in the aircraft application). In cutting through the granite to make the Millennium Arch the concern was more to ensure that when the central figure was completely outlined that there would be no protrusion that would stop the two parts of the piece being separated.

In traditional processing, it is common to expect that, after the pieces of an assembly have been separately cut out, that the part edges will be finished separately, before the components are brought together in final assembly. Thus, as an example, after using a cutting device to cut the shapes of different parts of an assembly, secondary finishing is built into the cost and time schedule to allow for this additional step of cleaning up the edges of the parts to remove the cut imperfections that form as a part of conventional cutting.

But, in many cases, the use of an abrasive waterjet system does not require that second step. The quality of the initial surface cut is well within the bounds of precision and accuracy that are required to meet the final assembly part requirements. As a result there is at least one, and often more steps that can be eliminated from the assembly schedule, and the costs for those set against any additional costs that the waterjet cutting costs might have initially brought into the overall picture. In assembly costs time is money, and the elimination of steps in a process can be significantly greater than just those occurred in the process itself. It is an advantage that is not often fully recognized.

Consider, for example, the simple case where two surfaces are to be riveted together. In the older, conventional practice the two parts would be mated one to the other, while a machinist came along and drilled the rivet holes through the two parts. The parts would then be separated while the burrs and machining residue was removed from the two pieces separately, and then they would be relocated and re-aligned, and a riveter would then come along and drive in the rivets to hold the parts together.

In contrast, where an abrasive waterjet is used the tool can cut through both (or more) parts without burring on the edge, leaving holes of high enough edge quality that there is no burring or need for subsequent re-finishing. The rivets can be immediately installed in the appropriate holes, which are already aligned and ready, and two lengthy and costly process steps can be saved.

As a trivial issue, but one of increasing importance as the cost of raw materials increases, the component pieces that are cut from the solid to make the two parts can also be recovered as a single piece, with the opportunity for use in another application, rather than being rendered down into scrap that must first be reconstituted in to a solid piece.

To continue with the analogy (though it is admittedly a bit hard to find a secondary use for metal of this shape) the metal removed from the rivet hole can be recovered in a single piece.

Figure 1. Rivet hole metal removed from a sample as a single piece, compared with the conventional alternative.

There is, however, one caveat to this discussion, and that relates to surfaces that will be precision welded after cutting. One of the problems that abrasive waterjets can create, is the occasional embedment of the abrasive particles within the cut surface. (Figure 2).

Figure 2. SEM image showing abrasive particles embedded in a surface after cutting. (Dr. Galecki)

Where this is a possible problem then the simple answer, as my colleague Dr. Greg Galecki has demonstrated, is to repeat the cutting path but with a high-pressure waterjet along feeding over the cut surface (at a higher traverse speed). This removed the buried pieces and leaves the surface in the condition required.

Figure 3. SEM image of cleaned surface showing a representative site where the embedded particle has been removed.

Labels:

cut quality,

cutting fruit,

NRC,

particle removal,

vegetables

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment