Showing posts with label abrasive waterjet. Show all posts

Showing posts with label abrasive waterjet. Show all posts

Friday, December 6, 2013

Waterjetting 16a - Abrasive Feed

I was talking with someone the other day who mentioned that it was necessary to increase the amount of abrasive feed to a waterjet whenever the material to be cut was thicker. This is actually a myth, or put another way, wrong! It is the equivalent of saying that you should use a duller knife if you want to cut thinner material.

Today’s topic therefore is about optimizing the abrasive feed rate into an abrasive waterjet cutting system, but you should remember that different manufacturers have different nozzle assembly designs. Thus the graphs and tables that I will use to illustrate the discussion relate to one particular nozzle design that was used at that time. Not all the nozzle designs were the same, but the results illustrate the points that I am going to make. But it underlies the recommendation that you should each run some standard tests with your system so that you have a baseline of performance and data to tell you where your system works best.

There are several reasons why different designs produce different cutting results, and I will point out some of them in what follows. To begin, however, consider again the basic elements of the waterjet mixing chamber.

Figure 1. Section through the mixing chamber of a conventional abrasive injection system.

A small high pressure stream of water enters the chamber through the upper nozzle, passes through the chamber, creating a vacuum that pulls abrasive into the chamber, and mixes with that abrasive before the resulting AWJ exits through the focusing tube.

One of the first things to understand is that, in the cutting jet that issues from the tube the actual cutting comes from the abrasive particles. From work that has been carried out at a number of places we know that the higher the velocity of the particles, the greater the damage that they will do on the target.

Figure 2. Relative mass loss when steel balls hit a mild steel plate (after Hutchings, I.M., Winter, R.E., Field, J.E., "Solid Particle Erosion of Metals;The Removal of Surface Material by Spherical Projectiles," Proceedings of the Royal Society, London, Vol. A348, 1976, pp. 379 - 392.)

Discussion in earlier posts pointed out that there are different ways in which waterjets attack ductile and brittle materials. However the relationship between an increase in impact velocity and damage occurs whether the targets are brittle or ductile. In figure 2 the target was a ductile steel, in more brittle material it is the coalescence of cracks that removes material, and higher velocities create larger cracks, as shown in figure 3.

Figure 3. Effect of impact velocity on crack length, (after Evans, A.G., "Impact Damage Mechanics: Solid Projectiles," in Erosion, Treatise on Materials Science and Technology, Vol. 16, ed C. Preece, Academic Press, 1979.).

And the same form holds true if steel balls are fired into sandstone.

Figure 4. Relative amount of Berea sandstone removed by the impact of steel balls of varying size (after Ripkin, J.F., Wetzel, J.M., A Study of the Fragmentation of Rock byImpingement with Water and Solid Impactors, Final Report on U.S. Bureau of Mines, Contract HO 210021, February, 1972.).

The above graphs show that it is more effective to have the abrasive moving faster in terms of the damage done by individual particles. Which brings up the first consideration in the design and use of an AWJ mixing chamber.

In order to get the particles moving as fast as possible they have to get their energy from the water jet entering the chamber. But the jet enters the chamber as a solid stream that then breaks into droplets (as shown in earlier pictures) as it passes down the chamber. If the jet remains in a solid stream all the way down, and out of the focusing tube, then the abrasive will find it difficult to penetrate into the center of the jet stream and pick up all the needed jet energy.

This can be illustrated by looking at the velocity and distribution of particles coming out of a nozzle with two different sizes of waterjet orifice but the same size of focusing tube diameter.

Figure 5. Relative particle distribution across a 40,000 psi jet with a focusing tube diameter of 2.3 mm (0.09 inches), and an AFR of 1 lb/min for two waterjet orifice sizes (after Mazurkiewicz, M., Olko, P., Jordan, R., "Abrasive Particle Distribution in a High Pressure Hydroabrasive Jet," International Water Jet Symposium, Beijing, China, September, 1987, pp. 4-1 - 4-10.)

The smaller waterjet breaks up fully within the chamber entraining and accelerating the abrasive particles and providing the desired cutting stream. The larger sized jet does not completely breakup, and fewer particles can mix into the center of the jet giving a more diffuse and less efficient cutting stream. In this case changing from a 0.005 inch waterjet orifice to a 0.013 inch diameter orifice (at roughly 7 times more power, because of the higher flow rate) produces a poorer result.

It is therefore important to ensure that there is an efficient energy transfer between the water and the particles. But the jet energy can only be diffused to a certain number of particles before it significantly begins to reduce in the amount of energy that it imparts to each particle. In other words if you put too much abrasive into the jet stream, then the amount of energy each particle gets is reduced, as it the overall cutting efficiency.

In an example I have used in class I noted that if I pick up a small child and run down the corridor, then I can carry the child at about my normal running speed, on the other hand if I pick up a couple of football players and try the same run I will be barely able to stagger. So the optimum carrying capacity of any jet can be determined for a given water flow rate, which is itself based on the waterjet orifice diameter and the pressure at which the water is supplied.

I will return to this topic next time, but you can see, in the concluding figure, that when a lower abrasive feed rate is fed to the nozzle, that the percentage of the abrasive moving in the higher velocity range rises to over 60% compared with only 20% of the particles when the abrasive feed is too high. And that means that the cutting performance will be less with the higher abrasive feed rates. (The numbers are a little high to reinforce the point).

Figure 7. Particle velocity distribution on leaving the focusing tube (after Isobe, T., Yoshida, H., Nishi, K., "Distribution of Abrasive Particles in Abrasive Water Jet and Acceleration Mechanism," paper E2, 9th International Symposium on Jet Cutting Technology, Sendai, Japan, Oct, 1988, pp. 217 - 238.)

Today’s topic therefore is about optimizing the abrasive feed rate into an abrasive waterjet cutting system, but you should remember that different manufacturers have different nozzle assembly designs. Thus the graphs and tables that I will use to illustrate the discussion relate to one particular nozzle design that was used at that time. Not all the nozzle designs were the same, but the results illustrate the points that I am going to make. But it underlies the recommendation that you should each run some standard tests with your system so that you have a baseline of performance and data to tell you where your system works best.

There are several reasons why different designs produce different cutting results, and I will point out some of them in what follows. To begin, however, consider again the basic elements of the waterjet mixing chamber.

Figure 1. Section through the mixing chamber of a conventional abrasive injection system.

A small high pressure stream of water enters the chamber through the upper nozzle, passes through the chamber, creating a vacuum that pulls abrasive into the chamber, and mixes with that abrasive before the resulting AWJ exits through the focusing tube.

One of the first things to understand is that, in the cutting jet that issues from the tube the actual cutting comes from the abrasive particles. From work that has been carried out at a number of places we know that the higher the velocity of the particles, the greater the damage that they will do on the target.

Figure 2. Relative mass loss when steel balls hit a mild steel plate (after Hutchings, I.M., Winter, R.E., Field, J.E., "Solid Particle Erosion of Metals;The Removal of Surface Material by Spherical Projectiles," Proceedings of the Royal Society, London, Vol. A348, 1976, pp. 379 - 392.)

Discussion in earlier posts pointed out that there are different ways in which waterjets attack ductile and brittle materials. However the relationship between an increase in impact velocity and damage occurs whether the targets are brittle or ductile. In figure 2 the target was a ductile steel, in more brittle material it is the coalescence of cracks that removes material, and higher velocities create larger cracks, as shown in figure 3.

Figure 3. Effect of impact velocity on crack length, (after Evans, A.G., "Impact Damage Mechanics: Solid Projectiles," in Erosion, Treatise on Materials Science and Technology, Vol. 16, ed C. Preece, Academic Press, 1979.).

And the same form holds true if steel balls are fired into sandstone.

Figure 4. Relative amount of Berea sandstone removed by the impact of steel balls of varying size (after Ripkin, J.F., Wetzel, J.M., A Study of the Fragmentation of Rock byImpingement with Water and Solid Impactors, Final Report on U.S. Bureau of Mines, Contract HO 210021, February, 1972.).

The above graphs show that it is more effective to have the abrasive moving faster in terms of the damage done by individual particles. Which brings up the first consideration in the design and use of an AWJ mixing chamber.

In order to get the particles moving as fast as possible they have to get their energy from the water jet entering the chamber. But the jet enters the chamber as a solid stream that then breaks into droplets (as shown in earlier pictures) as it passes down the chamber. If the jet remains in a solid stream all the way down, and out of the focusing tube, then the abrasive will find it difficult to penetrate into the center of the jet stream and pick up all the needed jet energy.

This can be illustrated by looking at the velocity and distribution of particles coming out of a nozzle with two different sizes of waterjet orifice but the same size of focusing tube diameter.

Figure 5. Relative particle distribution across a 40,000 psi jet with a focusing tube diameter of 2.3 mm (0.09 inches), and an AFR of 1 lb/min for two waterjet orifice sizes (after Mazurkiewicz, M., Olko, P., Jordan, R., "Abrasive Particle Distribution in a High Pressure Hydroabrasive Jet," International Water Jet Symposium, Beijing, China, September, 1987, pp. 4-1 - 4-10.)

The smaller waterjet breaks up fully within the chamber entraining and accelerating the abrasive particles and providing the desired cutting stream. The larger sized jet does not completely breakup, and fewer particles can mix into the center of the jet giving a more diffuse and less efficient cutting stream. In this case changing from a 0.005 inch waterjet orifice to a 0.013 inch diameter orifice (at roughly 7 times more power, because of the higher flow rate) produces a poorer result.

It is therefore important to ensure that there is an efficient energy transfer between the water and the particles. But the jet energy can only be diffused to a certain number of particles before it significantly begins to reduce in the amount of energy that it imparts to each particle. In other words if you put too much abrasive into the jet stream, then the amount of energy each particle gets is reduced, as it the overall cutting efficiency.

In an example I have used in class I noted that if I pick up a small child and run down the corridor, then I can carry the child at about my normal running speed, on the other hand if I pick up a couple of football players and try the same run I will be barely able to stagger. So the optimum carrying capacity of any jet can be determined for a given water flow rate, which is itself based on the waterjet orifice diameter and the pressure at which the water is supplied.

I will return to this topic next time, but you can see, in the concluding figure, that when a lower abrasive feed rate is fed to the nozzle, that the percentage of the abrasive moving in the higher velocity range rises to over 60% compared with only 20% of the particles when the abrasive feed is too high. And that means that the cutting performance will be less with the higher abrasive feed rates. (The numbers are a little high to reinforce the point).

Figure 7. Particle velocity distribution on leaving the focusing tube (after Isobe, T., Yoshida, H., Nishi, K., "Distribution of Abrasive Particles in Abrasive Water Jet and Acceleration Mechanism," paper E2, 9th International Symposium on Jet Cutting Technology, Sendai, Japan, Oct, 1988, pp. 217 - 238.)

Read more!

Labels:

abrasive cutting,

abrasive particles,

abrasive waterjet,

AFR

Sunday, December 1, 2013

Waterjetting 15d – More thoughts on cut surface quality.

When a high-pressure stream of water hits a surface, the arrival of subsequent lengths of the waterjet stream forces the initial water away from the initial impact point, into and along any weakness planes in the target material. As a result there is some preferential cutting of the material, especially where there are defined weakness planes in the material. One illustration of this is where a jet that contains cavitation bubbles impacts on a rock surface (figure 1) and as the water enters the narrow eroded channels where preceding lengths of water have preferentially eroded out the weaker rock the pressure in the channel increases, collapsing the remaining cavitation bubbles and further exacerbating the damage within that narrow channel, causing it (them) to grow preferentially relative to the surrounding rock.

Figure 1. Looking down into a channel cut by a cavitating jet that traversed from left to right, at a speed of 0.4 inches/minute. Note the preferential attack into weakness planes within the rock.

As the weakness planes grow and join, so individually larger pieces of rock can be broken free from the target and the path, and pressure profiles of the water in the cutting zone change quite significantly. For this cavitation to have a significant impact on the erosion pattern, however, the traverse speed over the surface must be controlled, and be relatively low. At more effective speeds the cutting process does not allow for the development of this fracture mechanism. Rather, with plain jets, the process concentrates just on crack growth around individual grains. Optimum cutting speeds are much higher, depending on the intended result.

The efficiency of waterjet cutting has, historically, been assessed in terms of how much energy is required to remove unit volume of material. This we call the specific energy of the cutting process, and a common unit is joules/cubic centimeter (j/cc). When using a waterjet to cut into material, in part because of the interference between different segments of the jet stream, pre and post impact, the most efficient cutting speeds are quite high.

Figure 2. The change in cutting efficiency with traverse speed of a high-pressure waterjet cutting stream

The downside to using higher cutting speeds (apart from the simple inertial problems in driving systems at higher speeds in other than straight lines) is that the depths of cut achieved become smaller on individual passes, as the jet has less cutting time on each path increment.

Figure 3. Change in cut depth as a function of traverse speed, for varying different rock types.

In linear cutting systems it is sometimes possible to align secondary or a higher multiple array of nozzles along the cut, so that thicker materials can be cut with a sequence of jet cuts along the same path. Alternately a single nozzle can make multiple passes along the cut path and sequentially deepen the slot.

Unfortunately while this is an effective way of solving some problems, it becomes less efficient as the slot gets deeper.

Figure 4. The change in cutting efficiency with increase in the number of cutting passes.

At higher pass numbers with the target surface at a growing distance from the nozzle, and with the edges of the cut starting to interfere with the free passage of the jet to the bottom of the cut, less energy is arriving at the bottom of the slot and thus the effectiveness falls.

While there are differences between abrasive waterjet cutting (where the optimal cutting speed is much lower than that for a plain high-pressure water jet) the form that the cutting jet takes through the target material is of similar shape in both circumstances.

Figure 5. An abrasive waterjet cut through 1-inch thick glass

As the jet cuts through the piece, so the cutting edge curves backwards from the top of the cut to the bottom. The rate of this curvature is, inter alia, a function of how fast the nozzle is moving over the surface. Dr. Ohlsson showed this effect in cutting through 0.4-inch thick aluminum and mild steel plates, back as part of his doctorate at Lulea in 1995.

Figure 6. Change in the cutting edge profiles and cut groove patterns in metals as a function of cutting speed (L. Ohlssson PhD Lulea, 1995)

The growth of the striations in the cut surface, as the depth of cut increases is one of the larger concerns with cut surface quality, since customers are often concerned that these be minimized, and further if they become large enough they can make it difficult to separate the pieces, particularly if the parts are cut with a complex geometry.

Early in the understanding of the way in which waterjets work, it was thought that the jet would incrementally cut strips from the material in front of the previous cut, inducing steps into the cutting plane that worked their way down the material.

Figure 7. Early concept of cutting front development (L. Ohlssson PhD Lulea, 1995)

However, as higher speed cameras recorded the development of the cutting front, this concept has been rethought. Henning, for example at the 18th ISJCT, used a camera taking 520 frames per second to establish the development of the cut profile as the jet cut through clear plastic. In figure 8 the profiles are shown as they developed at 35 frames/sec to allow them to be distinguished.

Figure 8. Cutting front development as an abrasive jet cuts from right to left (Henning 18th ISJCT)

As Ohlsson had shown this profile develops as the abrasive laden jet impacts then bounces, then impacts and cuts further into the material, as it moves down the cut.

Figure 9. Frames showing a sequence as an abrasive waterjet cuts through 2-inches of glass. ((L. Ohlssson PhD Lulea, 1995)

In his work Henning correlated the change in the “bounce angle” with the jet properties, while Ohlsson also correlated with the traverse speed.

Figure 10. Change in the “bounce” angle as an abrasive jet moves down the cut (Henning 18th ISJCT)

Two things should be remembered in this analysis, since they also explain causes of the increased roughness of the cut each time the jet bounces. The first is that the jet is not only laden with any initial abrasive, but as it cuts into the material, and removes it so that cut material is entrained in the jet, so that there is some abrasive cutting, even with a plain waterjet once the initial cut has been made. The second point is that when the jet bounces it is not constrained to bounce just in the plane of the cut, but can and does take up some deflection into the sides of the cut. Thus, with each bounce and reflection, the cut becomes rougher as that side cutting becomes more pronounced.

However the number of bounces can be slowed by slowing the speed at which the nozzle moves over the surface.

Figure 11. Change in the angle along the cutting edge as the speed of cutting and the jet pressure are changed (H. Louis, Waterjet Conference, Ishinomaki, 1999)

Henning uses a different term, but nevertheless it is clear that increasing the jet pressure and changing the diameter of the jet stream also controls the edge profile, and as discussed, with a smaller number of bounces so the edge quality improves.

Figure 12. The effect of changing jet pressure and jet diameter on the gradient of the cutting edge profile (Henning 18th ISJCT)

Figure 1. Looking down into a channel cut by a cavitating jet that traversed from left to right, at a speed of 0.4 inches/minute. Note the preferential attack into weakness planes within the rock.

As the weakness planes grow and join, so individually larger pieces of rock can be broken free from the target and the path, and pressure profiles of the water in the cutting zone change quite significantly. For this cavitation to have a significant impact on the erosion pattern, however, the traverse speed over the surface must be controlled, and be relatively low. At more effective speeds the cutting process does not allow for the development of this fracture mechanism. Rather, with plain jets, the process concentrates just on crack growth around individual grains. Optimum cutting speeds are much higher, depending on the intended result.

The efficiency of waterjet cutting has, historically, been assessed in terms of how much energy is required to remove unit volume of material. This we call the specific energy of the cutting process, and a common unit is joules/cubic centimeter (j/cc). When using a waterjet to cut into material, in part because of the interference between different segments of the jet stream, pre and post impact, the most efficient cutting speeds are quite high.

Figure 2. The change in cutting efficiency with traverse speed of a high-pressure waterjet cutting stream

The downside to using higher cutting speeds (apart from the simple inertial problems in driving systems at higher speeds in other than straight lines) is that the depths of cut achieved become smaller on individual passes, as the jet has less cutting time on each path increment.

Figure 3. Change in cut depth as a function of traverse speed, for varying different rock types.

In linear cutting systems it is sometimes possible to align secondary or a higher multiple array of nozzles along the cut, so that thicker materials can be cut with a sequence of jet cuts along the same path. Alternately a single nozzle can make multiple passes along the cut path and sequentially deepen the slot.

Unfortunately while this is an effective way of solving some problems, it becomes less efficient as the slot gets deeper.

Figure 4. The change in cutting efficiency with increase in the number of cutting passes.

At higher pass numbers with the target surface at a growing distance from the nozzle, and with the edges of the cut starting to interfere with the free passage of the jet to the bottom of the cut, less energy is arriving at the bottom of the slot and thus the effectiveness falls.

While there are differences between abrasive waterjet cutting (where the optimal cutting speed is much lower than that for a plain high-pressure water jet) the form that the cutting jet takes through the target material is of similar shape in both circumstances.

Figure 5. An abrasive waterjet cut through 1-inch thick glass

As the jet cuts through the piece, so the cutting edge curves backwards from the top of the cut to the bottom. The rate of this curvature is, inter alia, a function of how fast the nozzle is moving over the surface. Dr. Ohlsson showed this effect in cutting through 0.4-inch thick aluminum and mild steel plates, back as part of his doctorate at Lulea in 1995.

Figure 6. Change in the cutting edge profiles and cut groove patterns in metals as a function of cutting speed (L. Ohlssson PhD Lulea, 1995)

The growth of the striations in the cut surface, as the depth of cut increases is one of the larger concerns with cut surface quality, since customers are often concerned that these be minimized, and further if they become large enough they can make it difficult to separate the pieces, particularly if the parts are cut with a complex geometry.

Early in the understanding of the way in which waterjets work, it was thought that the jet would incrementally cut strips from the material in front of the previous cut, inducing steps into the cutting plane that worked their way down the material.

Figure 7. Early concept of cutting front development (L. Ohlssson PhD Lulea, 1995)

However, as higher speed cameras recorded the development of the cutting front, this concept has been rethought. Henning, for example at the 18th ISJCT, used a camera taking 520 frames per second to establish the development of the cut profile as the jet cut through clear plastic. In figure 8 the profiles are shown as they developed at 35 frames/sec to allow them to be distinguished.

Figure 8. Cutting front development as an abrasive jet cuts from right to left (Henning 18th ISJCT)

As Ohlsson had shown this profile develops as the abrasive laden jet impacts then bounces, then impacts and cuts further into the material, as it moves down the cut.

Figure 9. Frames showing a sequence as an abrasive waterjet cuts through 2-inches of glass. ((L. Ohlssson PhD Lulea, 1995)

In his work Henning correlated the change in the “bounce angle” with the jet properties, while Ohlsson also correlated with the traverse speed.

Figure 10. Change in the “bounce” angle as an abrasive jet moves down the cut (Henning 18th ISJCT)

Two things should be remembered in this analysis, since they also explain causes of the increased roughness of the cut each time the jet bounces. The first is that the jet is not only laden with any initial abrasive, but as it cuts into the material, and removes it so that cut material is entrained in the jet, so that there is some abrasive cutting, even with a plain waterjet once the initial cut has been made. The second point is that when the jet bounces it is not constrained to bounce just in the plane of the cut, but can and does take up some deflection into the sides of the cut. Thus, with each bounce and reflection, the cut becomes rougher as that side cutting becomes more pronounced.

However the number of bounces can be slowed by slowing the speed at which the nozzle moves over the surface.

Figure 11. Change in the angle along the cutting edge as the speed of cutting and the jet pressure are changed (H. Louis, Waterjet Conference, Ishinomaki, 1999)

Henning uses a different term, but nevertheless it is clear that increasing the jet pressure and changing the diameter of the jet stream also controls the edge profile, and as discussed, with a smaller number of bounces so the edge quality improves.

Figure 12. The effect of changing jet pressure and jet diameter on the gradient of the cutting edge profile (Henning 18th ISJCT)

Read more!

Friday, September 27, 2013

Waterjetting 13d - Pocket milling considerations

If I were to hand you a cake and suggest you take some, you would likely take a knife, and make two cuts to define a wedge of the cake, which you could then easily remove with your fingers, and easily eat.

Figure 1. Conventional cutting of a piece of cake.

However if one takes the approach used in many machine shops, and in many of the processes that are used to excavate soil and rock, then the process and product are a lot different. For, instead of just making two cuts that make it easy to remove and handle the product, instead the operator takes the knife and chops up the piece of cake into small particles.

Figure 2. Milling pockets into a piece of cake, with a pile of crumbs.

Now while it is true that this might produce nice clean pockets in the cake, it does leave the extracted cake in small pieces that cost a lot more energy to produce, are a lot more difficult to collect and handle, and are relatively worthless without being reprocessed back into a more useful form.

In some cases, where the cuts are made to the edge of the piece, it is not that difficult to adapt waterjet technology to emulate the knife in the above example. Cuts can be made along the edges of the pocket in such a way that they intersect within the piece to define a block of material that can be removed.

Figure 3. Piece of metal trimmed from a block in a form that allows it to be used for something else.

The savings can be considerable and are not restricted to small pieces such as this. Consider if you wish to create a tube, 2.5-inches long in Hastelloy. One could mill out the central volume to give the required shape:

Figure 4. Tube made from a block of Hastelloy

Or one could merely cut around the desired shape in the block, using a high-pressure abrasive waterjet, which would produce the central block as a single piece that could then be used as feed stock for another part.

Figure 5. Removed block of material from the piece shown in Figure 4. (For this initial demonstration the quality of the side cut was not considered important, it can be significantly improved for both internal and external surfaces, as discussed below).

Life becomes a little more complicated when the pocket must be generated without through cutting the part, and where the depths of the individual cuts must be precise, at the same time as the wall quality must my produced to final surface specifications.

There are a number of techniques that can be used in this case, depending on the material being cut, and on the depth that the pocket must be cut to. As mentioned in a previous piece, when higher quality surfaces are required then the cut must be made only with particles that have not cut, bounced and recut the work piece. Rather they must leave the cutting zone after the first cut, without further damage.

When the abrasive cutting conditions are controlled accurately, then the precision control in the depth of cut can be high, so that, for example, channels can be precisely cut into engine parts as needed.

Figure 6. Milled channels into a surface (note that the channels were deepened with three passes of the cutting head). (Courtesy Ormond)

In the above case the channels were narrow enough to be removed by the full width of the cutting jet, however, when larger pockets must be cut then this precision must be maintained over the full depth.

A problem that can then arise comes from the shape of the cut as it gets deeper. If the nozzle is not advanced into the cut (and this is not normally possible given the relative widths of the two) then there will normally be a slight taper into the cut as it deepens. With relatively thin work structure this taper will often be slight enough that it does not fall outside the tolerance required for the cut. Quality control can be achieved, therefore, with a series of rapidly moving nozzle, shallow individual cut passes. Omertz, for example, showed that a much better control of cut depth and wall quality can be achieved by twelve passes at a higher rate than a single pass over the surface with the same residence time on the part. However the optimal condition will depend on the tolerance on asperities in the floor, and the total depth of cut to be achieved, as well as the material being cut. In deeper parts the sides of the wall can narrow to interfere with the jet structure and create ripples that take the deeper wall surfaces beyond this acceptable limit.

Figure 7. Schematic of the jet structure as it moves away from the nozzle.

One solution to this is to return to the technology that we demonstrated with John Shepherd’s Wobbler namely to move the nozzle in such a way that the jet oscillates over the surface, not only making multiple passes along the floor of the desired cut at a high enough speed to achieve good depth control, but also by slightly widening the cut there is less chance of undesirable bounces from particles on the edge of the jet from causing out-of-tolerance rippling in the lower parts of the cut.

Figure 8. Exaggerated movement schematic to show how oscillating the head widens the cut, allowing the jet better access to the bottom of the cut without sidewall interference.

This particular aspect of nozzle motion has also been studied in Australia and Italy. The Australian results, for example, (Patel, Chen and Siores, 6th Pacific Rim Conference, Brisbane, 2000) looked at oscillation both along the cut and transverse to it. They found that surface quality was improved three-fold on the walls of the cut, and that, depending on oscillation angle and frequency, the smooth zone cut depth could be extended further into the work piece. The optimal angle of oscillation was found to be three degrees.

Figure 9. The effect of nozzle oscillation frequency on the depth of smooth cutting in the walls of the piece. (Patel, Chen and Siores, 6th Pacific Rim Conference, Brisbane, 2000)

How one breaks out the floor of the pocket, after defining the walls remains a work in progress.

Figure 1. Conventional cutting of a piece of cake.

However if one takes the approach used in many machine shops, and in many of the processes that are used to excavate soil and rock, then the process and product are a lot different. For, instead of just making two cuts that make it easy to remove and handle the product, instead the operator takes the knife and chops up the piece of cake into small particles.

Figure 2. Milling pockets into a piece of cake, with a pile of crumbs.

Now while it is true that this might produce nice clean pockets in the cake, it does leave the extracted cake in small pieces that cost a lot more energy to produce, are a lot more difficult to collect and handle, and are relatively worthless without being reprocessed back into a more useful form.

In some cases, where the cuts are made to the edge of the piece, it is not that difficult to adapt waterjet technology to emulate the knife in the above example. Cuts can be made along the edges of the pocket in such a way that they intersect within the piece to define a block of material that can be removed.

Figure 3. Piece of metal trimmed from a block in a form that allows it to be used for something else.

The savings can be considerable and are not restricted to small pieces such as this. Consider if you wish to create a tube, 2.5-inches long in Hastelloy. One could mill out the central volume to give the required shape:

Figure 4. Tube made from a block of Hastelloy

Or one could merely cut around the desired shape in the block, using a high-pressure abrasive waterjet, which would produce the central block as a single piece that could then be used as feed stock for another part.

Figure 5. Removed block of material from the piece shown in Figure 4. (For this initial demonstration the quality of the side cut was not considered important, it can be significantly improved for both internal and external surfaces, as discussed below).

Life becomes a little more complicated when the pocket must be generated without through cutting the part, and where the depths of the individual cuts must be precise, at the same time as the wall quality must my produced to final surface specifications.

There are a number of techniques that can be used in this case, depending on the material being cut, and on the depth that the pocket must be cut to. As mentioned in a previous piece, when higher quality surfaces are required then the cut must be made only with particles that have not cut, bounced and recut the work piece. Rather they must leave the cutting zone after the first cut, without further damage.

When the abrasive cutting conditions are controlled accurately, then the precision control in the depth of cut can be high, so that, for example, channels can be precisely cut into engine parts as needed.

Figure 6. Milled channels into a surface (note that the channels were deepened with three passes of the cutting head). (Courtesy Ormond)

In the above case the channels were narrow enough to be removed by the full width of the cutting jet, however, when larger pockets must be cut then this precision must be maintained over the full depth.

A problem that can then arise comes from the shape of the cut as it gets deeper. If the nozzle is not advanced into the cut (and this is not normally possible given the relative widths of the two) then there will normally be a slight taper into the cut as it deepens. With relatively thin work structure this taper will often be slight enough that it does not fall outside the tolerance required for the cut. Quality control can be achieved, therefore, with a series of rapidly moving nozzle, shallow individual cut passes. Omertz, for example, showed that a much better control of cut depth and wall quality can be achieved by twelve passes at a higher rate than a single pass over the surface with the same residence time on the part. However the optimal condition will depend on the tolerance on asperities in the floor, and the total depth of cut to be achieved, as well as the material being cut. In deeper parts the sides of the wall can narrow to interfere with the jet structure and create ripples that take the deeper wall surfaces beyond this acceptable limit.

Figure 7. Schematic of the jet structure as it moves away from the nozzle.

One solution to this is to return to the technology that we demonstrated with John Shepherd’s Wobbler namely to move the nozzle in such a way that the jet oscillates over the surface, not only making multiple passes along the floor of the desired cut at a high enough speed to achieve good depth control, but also by slightly widening the cut there is less chance of undesirable bounces from particles on the edge of the jet from causing out-of-tolerance rippling in the lower parts of the cut.

Figure 8. Exaggerated movement schematic to show how oscillating the head widens the cut, allowing the jet better access to the bottom of the cut without sidewall interference.

This particular aspect of nozzle motion has also been studied in Australia and Italy. The Australian results, for example, (Patel, Chen and Siores, 6th Pacific Rim Conference, Brisbane, 2000) looked at oscillation both along the cut and transverse to it. They found that surface quality was improved three-fold on the walls of the cut, and that, depending on oscillation angle and frequency, the smooth zone cut depth could be extended further into the work piece. The optimal angle of oscillation was found to be three degrees.

Figure 9. The effect of nozzle oscillation frequency on the depth of smooth cutting in the walls of the piece. (Patel, Chen and Siores, 6th Pacific Rim Conference, Brisbane, 2000)

How one breaks out the floor of the pocket, after defining the walls remains a work in progress.

Read more!

Labels:

abrasive waterjet,

edge quality,

milling,

nozzle oscillation,

pockets,

tolerance,

Wobbler

Wednesday, August 28, 2013

Waterjetting 12d - The heat of a waterjet cut

In the last three posts I have been discussing the quantity of heat that is created when machine tools are used in the cutting of rock, metals and other materials. The amount that the temperature of both the cutting tool and work piece material will increase, and the effect that this has on the cutting tool and the finished part can, as I have shown, be reduced if a quite small stream of high-pressure water is directed into the small zone where the cutting is taking place.

But what happens if the cutting process doesn’t use the large scale typical mechanical cutting tools, but instead uses the very small particles embedded within the jet stream itself as part of an abrasive waterjet cutting system? For many years the evidence, after the cut was over, indicated that there was very little heat build-up in the part, and the process appeared to be a “cold cut,” but there was no immediate evidence, because of the rapidity with which the cut was made. However, with advances in technology that limitation was removed, and research scientists at the University of Hannover have now been able to make temperature measurements during cutting. (A Thermographical Map of Tool and Workpiece During the Cutting Process by Plain Waterjet and Abrasive Waterjet up to 900 MPa, H. Louis, A. Schenk, F. Pude and M. Mohamed, 17th International Conference on Waterjet Cutting Technology).

The group used an infra-red camera connected into a computer to capture images as an abrasive waterjet cut into a target work sample. The instrument had been calibrated to show the color temperatures that the image revealed.

Figure 1. Temperatures read through an infrared camera as an abrasive jet cuts into a target plate. (H. Louis et al, ibid)

The arrangement by which the images were obtained was relatively simple:

Figure 2. Experimental arrangement allowing capture of the temperature build-up in the cutting head, the abrasive jet and the work piece during an AWJ cut (H. Louis et al, ibid).

During the course of the experiment the size of the cutting jet and the pressure were changed to find how these controlled the temperatures that were generated in the different parts of the operation. The work first examined the results when only a plain waterjet, without abrasive particles, was used in cutting.

Figure 3. Temperature build-up when plain waterjets (at 125,000 psi) are being used to cut a piece. (H. Louis et al, ibid)

Note that there is not a large amount of heat generated in the part, in this case a temperature rise to 126 Deg F was measured, though the temperature rise in the nozzle holder was similar in range. When the effects of jet flow and pressure were plotted, the role that an increase in pressure played in raising the part temperature around the cutting zone is clear. Note, in Figure 3, the region over which the temperature has been raised in the work piece.

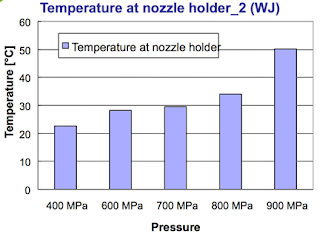

Figure 4. Temperature rise in the nozzle holder as a function of jet pressure. (H. Louis et al, ibid)

Note that at pressures of up to 100,000 psi (700 MPa) the temperature rise is only up to 86 deg F, much less than that in conventional mechanical cutting.

When abrasive is added to the jet stream, then the temperatures generated, as Figure 1 indicated, are higher in the nozzle holder, because of the impact of the particles with the focusing tube as part of the particle acceleration. The piece was moved under the jet at 1.2 inches/minute, with an abrasive feed of 0.06 lb/minute, with jet pressures varied from 42,000 psi to 115,000 psi. (300 to 800 MPa). The target was a metal alloy.

Not surprisingly as the pressure in the jet increased, so did the temperature in the focusing tube.

Figure 5. Temperature increase in the focusing tube, as a function of jet pressure (H. Louis et al, ibid).

Temperatures were measured at the top, middle and bottom of the cut which the AWJ made through the target material, and these are shown in the following plot:

Figure 6. Temperature build-up in the work piece during the cutting operation (H. Louis et al, ibid).

The graph shows that the temperature build-up is greatest in the middle of the cut, although this difference is small, and begins to disappear as the jet pressure increases. At 100,000 psi the temperature can rise to 150 deg F.

In most cutting work that temperature rise would not be enough to cause any damage to the part being cut. Where very temperature sensitive materials have been cut with the jet at lower pressures and higher speeds at MS&T the zone of influence of the cutting operation was measured in microns.

It is in living tissue, which can be more sensitive to temperature, where this can be a problem. The University in Hannover is internationally recognized for the work that it has been carrying out in to the use of high pressure waterjets in medical applications. While this is a subject for another day (or several since the range of applications continues to grow from year to year) the caution comes from work on cutting bone and reported at the 18th International Jet Cutting Conference in Gdansk by Biskup et al “Temperature measurement during abrasive water jet cutting of cortical bone measured by thermocouples”). Bear in mind, however, that one of the problems that the technology is seeking to address in these bone cutting experiments is to achieve a better quality cut than can be achieved with a hand saw, which has often been the tool used by a surgeon when dissecting bone, and the required edge quality is sometimes more difficult to achieve with that tool.

Figure 7. Temperature build-up in bone under varying conditions and for two bone thicknesses, as a function of residence time. (Biskup et al, ibid)

It can be seen that a thicker bone sample does become vulnerable to too high a temperature if there is a significant exposure time before the part is pierced. However, with an appropriate selection of parameters the temperature can be kept down in a range where the tissue does not die, and the considerable advantages to jet use can therefore be used.

Keeping the parts being cut cool is important in very delicate and precise work, where thermal distortion of the metal, particularly in thin but deep cuts, can otherwise lead to unacceptable failures to maintain tolerance.

But what happens if the cutting process doesn’t use the large scale typical mechanical cutting tools, but instead uses the very small particles embedded within the jet stream itself as part of an abrasive waterjet cutting system? For many years the evidence, after the cut was over, indicated that there was very little heat build-up in the part, and the process appeared to be a “cold cut,” but there was no immediate evidence, because of the rapidity with which the cut was made. However, with advances in technology that limitation was removed, and research scientists at the University of Hannover have now been able to make temperature measurements during cutting. (A Thermographical Map of Tool and Workpiece During the Cutting Process by Plain Waterjet and Abrasive Waterjet up to 900 MPa, H. Louis, A. Schenk, F. Pude and M. Mohamed, 17th International Conference on Waterjet Cutting Technology).

The group used an infra-red camera connected into a computer to capture images as an abrasive waterjet cut into a target work sample. The instrument had been calibrated to show the color temperatures that the image revealed.

Figure 1. Temperatures read through an infrared camera as an abrasive jet cuts into a target plate. (H. Louis et al, ibid)

The arrangement by which the images were obtained was relatively simple:

Figure 2. Experimental arrangement allowing capture of the temperature build-up in the cutting head, the abrasive jet and the work piece during an AWJ cut (H. Louis et al, ibid).

During the course of the experiment the size of the cutting jet and the pressure were changed to find how these controlled the temperatures that were generated in the different parts of the operation. The work first examined the results when only a plain waterjet, without abrasive particles, was used in cutting.

Figure 3. Temperature build-up when plain waterjets (at 125,000 psi) are being used to cut a piece. (H. Louis et al, ibid)

Note that there is not a large amount of heat generated in the part, in this case a temperature rise to 126 Deg F was measured, though the temperature rise in the nozzle holder was similar in range. When the effects of jet flow and pressure were plotted, the role that an increase in pressure played in raising the part temperature around the cutting zone is clear. Note, in Figure 3, the region over which the temperature has been raised in the work piece.

Figure 4. Temperature rise in the nozzle holder as a function of jet pressure. (H. Louis et al, ibid)

Note that at pressures of up to 100,000 psi (700 MPa) the temperature rise is only up to 86 deg F, much less than that in conventional mechanical cutting.

When abrasive is added to the jet stream, then the temperatures generated, as Figure 1 indicated, are higher in the nozzle holder, because of the impact of the particles with the focusing tube as part of the particle acceleration. The piece was moved under the jet at 1.2 inches/minute, with an abrasive feed of 0.06 lb/minute, with jet pressures varied from 42,000 psi to 115,000 psi. (300 to 800 MPa). The target was a metal alloy.

Not surprisingly as the pressure in the jet increased, so did the temperature in the focusing tube.

Figure 5. Temperature increase in the focusing tube, as a function of jet pressure (H. Louis et al, ibid).

Temperatures were measured at the top, middle and bottom of the cut which the AWJ made through the target material, and these are shown in the following plot:

Figure 6. Temperature build-up in the work piece during the cutting operation (H. Louis et al, ibid).

The graph shows that the temperature build-up is greatest in the middle of the cut, although this difference is small, and begins to disappear as the jet pressure increases. At 100,000 psi the temperature can rise to 150 deg F.

In most cutting work that temperature rise would not be enough to cause any damage to the part being cut. Where very temperature sensitive materials have been cut with the jet at lower pressures and higher speeds at MS&T the zone of influence of the cutting operation was measured in microns.

It is in living tissue, which can be more sensitive to temperature, where this can be a problem. The University in Hannover is internationally recognized for the work that it has been carrying out in to the use of high pressure waterjets in medical applications. While this is a subject for another day (or several since the range of applications continues to grow from year to year) the caution comes from work on cutting bone and reported at the 18th International Jet Cutting Conference in Gdansk by Biskup et al “Temperature measurement during abrasive water jet cutting of cortical bone measured by thermocouples”). Bear in mind, however, that one of the problems that the technology is seeking to address in these bone cutting experiments is to achieve a better quality cut than can be achieved with a hand saw, which has often been the tool used by a surgeon when dissecting bone, and the required edge quality is sometimes more difficult to achieve with that tool.

Figure 7. Temperature build-up in bone under varying conditions and for two bone thicknesses, as a function of residence time. (Biskup et al, ibid)

It can be seen that a thicker bone sample does become vulnerable to too high a temperature if there is a significant exposure time before the part is pierced. However, with an appropriate selection of parameters the temperature can be kept down in a range where the tissue does not die, and the considerable advantages to jet use can therefore be used.

Keeping the parts being cut cool is important in very delicate and precise work, where thermal distortion of the metal, particularly in thin but deep cuts, can otherwise lead to unacceptable failures to maintain tolerance.

Read more!

Wednesday, July 10, 2013

Waterjetting 11a - More thoughts on Abrasive

In the last post I mentioned that the abrasive particles, which are fed into a high-pressure waterjet stream to form the Abrasive WaterJet (AWJ) cutting tool, can be significantly crushed when mixing with the high-pressure waterjet, and before they leave the mixing chamber. Because of this - depending on the application - the choice of abrasive can play a significant role in how well the AWJ performs. I have mentioned a number of times that the Waterjet Lab is located at Missouri University of Science and Technology. That meant (apropos “show me”) that it was an appropriate place to run comparative tests between different abrasives to find which is the best.

It turns out that there is no one single answer to that question, since the abrasive that was the most economical and effective to use in one case does not necessarily give the best results in another. Which brings me to the first point in today’s post. It is relatively easy to get small samples of the different abrasives that might be used in a given job. Setting up a small series of test runs, in which the different abrasives being considered, are fed to the nozzle and use to cut standard cuts into test samples, is a relatively easy way to find out which is the best abrasive for that particular material and cutting path. However it is best not to use only a single test run, we would generally run a series with three different jet pressures and three different abrasive feed rates.

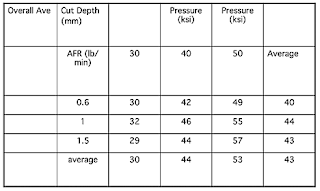

Figure 1. Table showing the change in optimal Abrasive Feed Rate (AFR) on cut depth at different pressures.

By bracketing the range that is likely to have the best concentration of abrasive for each pressure (which is not at the same abrasive feed rate, or AFR) the best result can be found for each different pressure value, and the most economical and effective choice for the task in hand can be quickly found. It is important to include economics in the evaluation, since there have been a number of cases we looked at where the most effective choice for abrasive in terms of giving the fastest clean cut was not that much more effective than the second place abrasive, and that alternative was sufficiently cheaper that it made more sense to use it.

The pricing of abrasive, however, is not something that it is easy to generalize over, since there are a number of different factors that come into play, depending where in the country you are located. As a rough guidance, however, we have found that garnet is a more universal cutting abrasive than most others, with less extraneous “issues”, and while it can be less effective than other selections in some conditions, in general it will cut more materials effectively and economically than its challengers. Further mined garnet, in general, performs better than alluvial garnet since it does not have the degree of damage within the particles that leads them to fragment more easily in the mixing chamber.

There are, however, more factors that just the abrasive type that have to be considered. There include the particle size, and range, and then, as noted in the table, there is the selection of the AFR to match the cutting conditions on the table.

One of the more neglected factors relates to the amount of air that is used to carry the abrasive from the hopper into the mixing chamber. The person who did more to shine a light into this corner of the technology was Tabitz, in France. (Tabitz, Schmidt, Parsy, Abriak, and Thery “Effect of Air on accceleration process in AWJ entrainment system, 12th ISJCT, Rouen, 1994 p 47 - 58.)

Because abrasive can cut into the parts of the flow meter, the equipment that they used included a trap between the hopper and the mixing chamber, where the particles could be collected, while the air passed forward to be measured and enter the mixing chamber.

Figure 2. Apparatus used by Tabitz in measuring the air flow to the cutting head and mixing chamber. (ibid)

The results from the measurement showed that as the jet pressure increased, so for that particular nozzle design, did the amount of air that was being drawn into the chamber – although you may note that it begins to reach a constant volume as the pressure approaches 280 MPa (40,000 psi).

Figure 3. Effect of increased jet pressure on the amount of air drawn into the nozzle, as a percentage of the total volume of the resulting jet. (Tabitz et al)

The problem that this relatively large volume of air presents is that it has to be accelerated at the same time as the energy in the jet is being transferred to the abrasive particles. The larger the amount of air in the mix, then the greater the amount of water energy that has to be diverted into accelerating the air. This leaves less energy available to accelerate the abrasive itself.

Tabitz modeled the result with a simulation in a computer program, which illustrates, for different abrasive feed rates, how the average abrasive particle velocity falls as the amount of air in the mix increases:

Figure 4. Simulated effect of an increase in air flow on the reduction in average abrasive particle velocity (after Tabitz et al).

Placing small instruments in front of abrasive-laden waterjets can lead to a relatively short life for those instruments, and measurements of actual particle velocities, though they have been made by a number of researchers, have not been as comprehensive as the above chart might indicate.

Nevertheless there is some indication that the above curves are accurate in principle, if not totally real. A jet with very little air might accelerate particles to 1,880 ft/sec, for example. However with 70% air in the mix, then the particle velocity might fall to 1,700 ft/sec, and with 95% of the jet made up of air, then the abrasive particle speed may fall to 1,200 ft/sec. Part of the difficulty in assessment is because of the very short time interval in which the abrasive particles are accelerated while in the mixing chamber. Because the rate of acceleration of the particles is inversely related to their size. Smaller particles are accelerated faster. And this is the counter to the point that was made in the last post about smaller particles cutter less efficiently than larger ones.

Part of the reason for this is that the smaller particles are decelerated faster in air than larger particles. The results of this in terms of cutting power is one of the areas that still requires more research. If, for example, smaller particles are used in an application (for example to achieve a finer detail in the surface cutting) then the effective range of the jet can become smaller than with larger particles. There are some caveats to that statement, and I will go into some of that explanation in the next post.

It turns out that there is no one single answer to that question, since the abrasive that was the most economical and effective to use in one case does not necessarily give the best results in another. Which brings me to the first point in today’s post. It is relatively easy to get small samples of the different abrasives that might be used in a given job. Setting up a small series of test runs, in which the different abrasives being considered, are fed to the nozzle and use to cut standard cuts into test samples, is a relatively easy way to find out which is the best abrasive for that particular material and cutting path. However it is best not to use only a single test run, we would generally run a series with three different jet pressures and three different abrasive feed rates.

Figure 1. Table showing the change in optimal Abrasive Feed Rate (AFR) on cut depth at different pressures.

By bracketing the range that is likely to have the best concentration of abrasive for each pressure (which is not at the same abrasive feed rate, or AFR) the best result can be found for each different pressure value, and the most economical and effective choice for the task in hand can be quickly found. It is important to include economics in the evaluation, since there have been a number of cases we looked at where the most effective choice for abrasive in terms of giving the fastest clean cut was not that much more effective than the second place abrasive, and that alternative was sufficiently cheaper that it made more sense to use it.

The pricing of abrasive, however, is not something that it is easy to generalize over, since there are a number of different factors that come into play, depending where in the country you are located. As a rough guidance, however, we have found that garnet is a more universal cutting abrasive than most others, with less extraneous “issues”, and while it can be less effective than other selections in some conditions, in general it will cut more materials effectively and economically than its challengers. Further mined garnet, in general, performs better than alluvial garnet since it does not have the degree of damage within the particles that leads them to fragment more easily in the mixing chamber.

There are, however, more factors that just the abrasive type that have to be considered. There include the particle size, and range, and then, as noted in the table, there is the selection of the AFR to match the cutting conditions on the table.

One of the more neglected factors relates to the amount of air that is used to carry the abrasive from the hopper into the mixing chamber. The person who did more to shine a light into this corner of the technology was Tabitz, in France. (Tabitz, Schmidt, Parsy, Abriak, and Thery “Effect of Air on accceleration process in AWJ entrainment system, 12th ISJCT, Rouen, 1994 p 47 - 58.)

Because abrasive can cut into the parts of the flow meter, the equipment that they used included a trap between the hopper and the mixing chamber, where the particles could be collected, while the air passed forward to be measured and enter the mixing chamber.

Figure 2. Apparatus used by Tabitz in measuring the air flow to the cutting head and mixing chamber. (ibid)

The results from the measurement showed that as the jet pressure increased, so for that particular nozzle design, did the amount of air that was being drawn into the chamber – although you may note that it begins to reach a constant volume as the pressure approaches 280 MPa (40,000 psi).

Figure 3. Effect of increased jet pressure on the amount of air drawn into the nozzle, as a percentage of the total volume of the resulting jet. (Tabitz et al)

The problem that this relatively large volume of air presents is that it has to be accelerated at the same time as the energy in the jet is being transferred to the abrasive particles. The larger the amount of air in the mix, then the greater the amount of water energy that has to be diverted into accelerating the air. This leaves less energy available to accelerate the abrasive itself.

Tabitz modeled the result with a simulation in a computer program, which illustrates, for different abrasive feed rates, how the average abrasive particle velocity falls as the amount of air in the mix increases:

Figure 4. Simulated effect of an increase in air flow on the reduction in average abrasive particle velocity (after Tabitz et al).

Placing small instruments in front of abrasive-laden waterjets can lead to a relatively short life for those instruments, and measurements of actual particle velocities, though they have been made by a number of researchers, have not been as comprehensive as the above chart might indicate.

Nevertheless there is some indication that the above curves are accurate in principle, if not totally real. A jet with very little air might accelerate particles to 1,880 ft/sec, for example. However with 70% air in the mix, then the particle velocity might fall to 1,700 ft/sec, and with 95% of the jet made up of air, then the abrasive particle speed may fall to 1,200 ft/sec. Part of the difficulty in assessment is because of the very short time interval in which the abrasive particles are accelerated while in the mixing chamber. Because the rate of acceleration of the particles is inversely related to their size. Smaller particles are accelerated faster. And this is the counter to the point that was made in the last post about smaller particles cutter less efficiently than larger ones.

Part of the reason for this is that the smaller particles are decelerated faster in air than larger particles. The results of this in terms of cutting power is one of the areas that still requires more research. If, for example, smaller particles are used in an application (for example to achieve a finer detail in the surface cutting) then the effective range of the jet can become smaller than with larger particles. There are some caveats to that statement, and I will go into some of that explanation in the next post.

Read more!

Saturday, June 29, 2013

Waterjetting 10d - Abrasive sizing

Over the past 30 years abrasive waterjet cutting has become an increasingly useful tool for cutting a wide range of materials, of varying thickness and strength. However, as the range of applications for the tool has grown, so the requirements for improved performance have also risen. Before being able to make a better quality cut there had to be a better understanding of how abrasive waterjet cutting works, so that the improvements could be made.

Figure 1. Some factors that affect the cutting performance of an abrasive waterjet (After Mazurkiewicz)

This understanding has not been easy to develop, since there are many different factors that all affect how well the cutting process takes place. Consider, first of all, the process of getting the abrasive up to the fastest speed possible. And for the purpose of discussion I am going to use a “generic” mixing chamber and focusing tube nozzle for the following discussion.

Figure 2. Simplified sketch of a mixing chamber and focusing tube nozzle used in adding abrasive to a high pressure waterjet.

As high-pressure water flows through the small orifice (which in the sketch was historically made of sapphire) it enters a larger mixing chamber and creates a suction that will pull abrasive into the mixing chamber through the side passage. That side passage is connected, through a tube, to a form of abrasive feed mechanism, that I will not discuss in detail today.

However the abrasive does not flow into the mixing chamber by itself. Rather it is transported into the mixing chamber using a fluid carrier. In the some of the earliest models of abrasive waterjet systems water was used as the carrier fluid to bring the abrasive into the mixing chamber. This, as a general rule, turned out to be a mistake.

The problem is that, within the mixing chamber, the energy that comes into the chamber with the high-pressure water has to mix, not only with the abrasive, but also with the fluid that carried the abrasive into the chamber. Water is heavier than air, and so if water is the carrier fluid, then it will absorb more of the energy that is available, with the result that there is less for the abrasive, which – as a result – does not move as quickly and therefore does not cut as well. The principle was first discussed by John Griffiths at the 2nd U.S. Waterjet Conference, although he was discussing abrasive use in cleaning at the time.

Figure 3 Difference in performance of water acting to carry the abrasive to the mixing chamber (wet feed) in contrast with the use of air as the carrier fluid. (Griffiths, J.J., "Abrasive Injection Usage in the United Kingdom," 2nd U.S. Waterjet Conference, May, 1983, Rolla, MO, pp. 423 - 432.)

Note that this is not the same as directly mixing the abrasive into the waterjet stream under pressure – abrasive slurry jetting – which I will discuss in later posts.

The difference between the two ways of bringing the abrasive to the mixing chamber is clear enough that almost from the beginning only air has been considered as the carrier to bring the abrasive into the mixing chamber. However there is the question as to how much air is enough, how much abrasive should be added, and how effectively the mixing process takes place.

In the earlier developments the equipment available restricted the range of pressures and flow rates at which the high pressure water could be supplied, and these limits bounded early work on the subject.

One early observation, however, was that the size of the abrasive that was being fed into the mixing chamber was not the average size of the abrasive after cutting was over. (At that time steel was not normally used as a cutting abrasive). Because the fracture of the abrasive into smaller pieces might mean that the cutting process became less effective, Greg Galecki and Marian Mazurkiewicz began to measure particle sizes, at different points in the process. (Galecki, G., Mazurkiewicz, M., Jordan, R., "Abrasive Grain Disintegration Effect During Jet Injection," International Water Jet Symposium,Beijing, China, September, 1987, pp. 4-71 - 4-77.)

For example, by firing the abrasive-laden jet along the axis of a larger plastic tube (here opened to show the construction) the abrasive would, after leaving the nozzle, decelerate and settle into the bottom of the tube, without further break-up, and without damage to the tube. Among other results this allowed a measure of how fast the particles leave the nozzle, since the faster they were moving, then the further they would carry down the pipe.

Figure 4. Test to examine particle size and travel distance, after leaving the AWJ nozzle at the left of the picture. The containing tube has divisions every foot, and small holes over blue containers, so that the amount caught in every foot could be collected and measured.

For one particular test the abrasive going into the system was carefully screened to be lie in the size range between 170 and 210 microns. It was then fed into a 30,000 psi waterjet at a feed rate of 0.6 lb/minute. The particles were captured, after passing through the mixing chamber, but before they could cut anything, by using the tube shown in Figure 4. The size of the particles was then measured, and plotted as a cumulative percentage adding the percentages found at each sieve size over the range to the 210 micron size of the starting particles.

Figure 5. Average size of particles after passing through a mixing chamber and exiting into a capture tube, without further damaging impact.

The horizontal line shows the point where 50% of the abrasive (by weight) had accumulated, and the vertical line shows that this is at a particle size of 140 microns. Thus, just in the mixing process alone energy is lost in mixing the very fast moving water, with the initially much slower moving abrasive.

And, as an aside, this is where the proper choice of abrasive becomes an important part of an effective cutting operation. Because the distribution of the curve shown in figure 5 will change, with abrasive type, size, concentration added, as well as the pressure and flow rate of the nozzle through which the water enters the mixing chamber.

I will have more to discuss on this in the next post, but will leave you with the following result. After we had run the tests which I just mentioned, we collected the abrasive in the different size ranges. Then we used those different size ranges to see how well the abrasive cut. This was one of the results that we found.

Figure 6. The effect of the size of the feed particles into the abrasive cutting system on the depth of cut which the AWJ achieved.

You will note that down to a size of around 100 microns the particle size did not make any significant difference, but that once the particle size falls below that range, then the cutting performance degrades considerably. (And if you go back to figure 5, you will note that about 30% of the abrasive fell into that size range, after the jet had left the mixing chamber).

Figure 1. Some factors that affect the cutting performance of an abrasive waterjet (After Mazurkiewicz)

This understanding has not been easy to develop, since there are many different factors that all affect how well the cutting process takes place. Consider, first of all, the process of getting the abrasive up to the fastest speed possible. And for the purpose of discussion I am going to use a “generic” mixing chamber and focusing tube nozzle for the following discussion.

Figure 2. Simplified sketch of a mixing chamber and focusing tube nozzle used in adding abrasive to a high pressure waterjet.

As high-pressure water flows through the small orifice (which in the sketch was historically made of sapphire) it enters a larger mixing chamber and creates a suction that will pull abrasive into the mixing chamber through the side passage. That side passage is connected, through a tube, to a form of abrasive feed mechanism, that I will not discuss in detail today.

However the abrasive does not flow into the mixing chamber by itself. Rather it is transported into the mixing chamber using a fluid carrier. In the some of the earliest models of abrasive waterjet systems water was used as the carrier fluid to bring the abrasive into the mixing chamber. This, as a general rule, turned out to be a mistake.

The problem is that, within the mixing chamber, the energy that comes into the chamber with the high-pressure water has to mix, not only with the abrasive, but also with the fluid that carried the abrasive into the chamber. Water is heavier than air, and so if water is the carrier fluid, then it will absorb more of the energy that is available, with the result that there is less for the abrasive, which – as a result – does not move as quickly and therefore does not cut as well. The principle was first discussed by John Griffiths at the 2nd U.S. Waterjet Conference, although he was discussing abrasive use in cleaning at the time.

Figure 3 Difference in performance of water acting to carry the abrasive to the mixing chamber (wet feed) in contrast with the use of air as the carrier fluid. (Griffiths, J.J., "Abrasive Injection Usage in the United Kingdom," 2nd U.S. Waterjet Conference, May, 1983, Rolla, MO, pp. 423 - 432.)

Note that this is not the same as directly mixing the abrasive into the waterjet stream under pressure – abrasive slurry jetting – which I will discuss in later posts.

The difference between the two ways of bringing the abrasive to the mixing chamber is clear enough that almost from the beginning only air has been considered as the carrier to bring the abrasive into the mixing chamber. However there is the question as to how much air is enough, how much abrasive should be added, and how effectively the mixing process takes place.

In the earlier developments the equipment available restricted the range of pressures and flow rates at which the high pressure water could be supplied, and these limits bounded early work on the subject.

One early observation, however, was that the size of the abrasive that was being fed into the mixing chamber was not the average size of the abrasive after cutting was over. (At that time steel was not normally used as a cutting abrasive). Because the fracture of the abrasive into smaller pieces might mean that the cutting process became less effective, Greg Galecki and Marian Mazurkiewicz began to measure particle sizes, at different points in the process. (Galecki, G., Mazurkiewicz, M., Jordan, R., "Abrasive Grain Disintegration Effect During Jet Injection," International Water Jet Symposium,Beijing, China, September, 1987, pp. 4-71 - 4-77.)

For example, by firing the abrasive-laden jet along the axis of a larger plastic tube (here opened to show the construction) the abrasive would, after leaving the nozzle, decelerate and settle into the bottom of the tube, without further break-up, and without damage to the tube. Among other results this allowed a measure of how fast the particles leave the nozzle, since the faster they were moving, then the further they would carry down the pipe.

Figure 4. Test to examine particle size and travel distance, after leaving the AWJ nozzle at the left of the picture. The containing tube has divisions every foot, and small holes over blue containers, so that the amount caught in every foot could be collected and measured.

For one particular test the abrasive going into the system was carefully screened to be lie in the size range between 170 and 210 microns. It was then fed into a 30,000 psi waterjet at a feed rate of 0.6 lb/minute. The particles were captured, after passing through the mixing chamber, but before they could cut anything, by using the tube shown in Figure 4. The size of the particles was then measured, and plotted as a cumulative percentage adding the percentages found at each sieve size over the range to the 210 micron size of the starting particles.

Figure 5. Average size of particles after passing through a mixing chamber and exiting into a capture tube, without further damaging impact.

The horizontal line shows the point where 50% of the abrasive (by weight) had accumulated, and the vertical line shows that this is at a particle size of 140 microns. Thus, just in the mixing process alone energy is lost in mixing the very fast moving water, with the initially much slower moving abrasive.

And, as an aside, this is where the proper choice of abrasive becomes an important part of an effective cutting operation. Because the distribution of the curve shown in figure 5 will change, with abrasive type, size, concentration added, as well as the pressure and flow rate of the nozzle through which the water enters the mixing chamber.

I will have more to discuss on this in the next post, but will leave you with the following result. After we had run the tests which I just mentioned, we collected the abrasive in the different size ranges. Then we used those different size ranges to see how well the abrasive cut. This was one of the results that we found.

Figure 6. The effect of the size of the feed particles into the abrasive cutting system on the depth of cut which the AWJ achieved.

You will note that down to a size of around 100 microns the particle size did not make any significant difference, but that once the particle size falls below that range, then the cutting performance degrades considerably. (And if you go back to figure 5, you will note that about 30% of the abrasive fell into that size range, after the jet had left the mixing chamber).

Read more!

Wednesday, June 19, 2013

Waterjetting 10c - Abrasive waterjet cutting

There are a number of different abrasives that can be supplied by different sources, and the market for the small grains that are used in abrasive waterjet cutting extends considerably beyond just the waterjet business. All abrasives are not created equal, some work better in one condition, others in another. As with other tools that the waterjet cutter or cleaner will use, first you should decide what the need for the abrasive is, and run a small series of tests to find out which is the best set of cutting conditions for that particular job.