Showing posts with label nozzle design. Show all posts

Showing posts with label nozzle design. Show all posts

Sunday, June 7, 2015

Waterjetting 34a - Drilling holes with water jets

Looking back over the Waterjet Index I realized that while I have addressed different aspects of drilling holes with waterjets in various ways, I haven’t really brought it all together as a focused topic. So, herewith, and in the next few posts, that coalescence. It begins with a bit of a recap.

It was clear, early in the work on waterjet applications, that one of the key problems to be addressed was that of the ingoing water having to fight its way past the spent water already exiting the hole that had been created. This is particularly true when making an initial pierce through a target material, where there is very little relative movement between the nozzle and the target. Given that the interaction between the two flows occurs within about a hundredth of a second, the effect on cutting efficiency is relatively immediate.

So how to overcome the problem? One way is to pulse the jet, and in some early work at Leeds we built such a pulsating unit and spun it in front of the nozzle, chopping the jet into segments and allowing one segment to leave the hole, before the next arrived.

Figure 1. Pulsating disc to rotate ahead of nozzle and “pulse” the jet.

This was inefficient, because the energy put into the segments diverted by the disc was lost, and it was also extremely noisy, to the point that tests had to be carried out after everyone else left the building.

The alternative was to rotate the sample (this was in the days before high-pressure swivels and couplings were available) and align the jet just off the axis of rotation, so that the jet cut a hole somewhat wider than itself, as it passed over the target and thus provided an open path for the rebounding spent water that did not interfere with the path of the fresh jet travelling to the impact point.

A comparison of relative penetration rates showed that while a fixed nozzle and steady jet had sensibly stopped penetrating after about a second, the pulsed jet continued to drill a hole, as did the rotating jet, but the latter was able to drill faster and remove more material.

Figure 2. Comparison of a steady jet, a pulsating jet and a rotating jet as they penetrate into rock over time. All jets are at the same diameter, pressure and standoff distance.

By moving the nozzle out to a greater radius the hole created could be enlarged. This allowed the nozzle to move forward into the cavity created and the process could be repeated. In this way, over several iterations, a waterjet at a pressure of about 9,500 psi drilled though a block of granite, uniaxial compressive strength around 30,000 psi, and a new drilling tool had been demonstrated.

Obviously it is impractical to keep enlarging the hole by reaming it wider from the surface to allow the nozzle body to enter the hole and advance to the bottom. The jet must, from the beginning, drill a hole large enough for the nozzle to advance. And the easy way to do this is to incline the nozzle (at an optimal angle of around 20 deg, depending on the pressure, the type of waterjet and the target material properties). And while we still did not have a rotating swivel, we could turn and raise the target, while directing the jet through a small inclined orifice.

Figure 3. Inclined jet drilling a hole through a rock

Skip forward a couple of years, and we were drilling rock, at a rate of about 4-inches a minute, with a single jet. Then Jim Blaine, the RMERC machinist at the time, misunderstood a drawing, and added a central axially aligned orifice to the nozzle geometry. And within days we had increased the speed of drilling by two orders of magnitude. (Though by this time we also had a working rotating coupling to help rotate the nozzle).

Figure 4. Modified drill nozzle geometry

Figure 5. Drilling rate of advance as a function of hole diameter and rotation speed.

When one is using a single jet to cut the required profile of the hole, which must exceed the diameter of the nozzle holder if the drill is to advance into the hole, the rotation speed of the drill must be fast enough, relative to the rotation that the ribs of material left between adjacent passes of the jet along the hole wall are either non-existent (where the adjacent passes overlap) or are small enough that the mechanical impact of the nozzle body can break them off with very little force. In the latter case, however, this can put a mechanical load onto the drill string. The drill is often made up of only a length of high-pressure tubing, with the nozzle threaded on the end, so that any significant mechanical force can distort it and cause the drill to misalign and no longer drill a straight hole, so that this contact is discouraged.

On the other hand the rock through which the drill passes will likely change in strength and composition quite frequently, and so the depth to which the jet will cut will also change. This means that the hole diameter may reduce, so that the hole is no longer large enough to allow the nozzle body to pass. To stop this becoming a problem a small ring is mounted ahead of the nozzle, in the plane that the jet reaches the hole diameter required in this particular case. Now when the jet fails to cut to that diameter then the ring will stop the drill advancing, while the jet cuts along the line of contact and enlarges the hole to the required size, then allowing the drill to move forward. This is helped where the drill is spring-loaded so that the compression of the spring stops the drill advance, and the relaxing of the spring, as the obstacle is removed, allows the drill to move forward again.

Figure 6. Gaging ring on the front of a drilling nozzle.

That drill development was relatively straightforward, and was demonstrated in the late 1970’s. Subsequently commercial drilling systems were developed that used high-pressure water to drill holes in mine rock. They had the advantage over conventional tools in that the hose feeding the nozzle could maneuver in a much smaller space than a conventional drill, and thus longer holes could be more easily drilled from narrow working areas.

Unfortunately it still proved difficult to drill all rock with a plain waterjet, despite the use of ultra-high pressure equipment, and two different approaches were then tried, which I will discuss in the next posts.

It was clear, early in the work on waterjet applications, that one of the key problems to be addressed was that of the ingoing water having to fight its way past the spent water already exiting the hole that had been created. This is particularly true when making an initial pierce through a target material, where there is very little relative movement between the nozzle and the target. Given that the interaction between the two flows occurs within about a hundredth of a second, the effect on cutting efficiency is relatively immediate.

So how to overcome the problem? One way is to pulse the jet, and in some early work at Leeds we built such a pulsating unit and spun it in front of the nozzle, chopping the jet into segments and allowing one segment to leave the hole, before the next arrived.

Figure 1. Pulsating disc to rotate ahead of nozzle and “pulse” the jet.

This was inefficient, because the energy put into the segments diverted by the disc was lost, and it was also extremely noisy, to the point that tests had to be carried out after everyone else left the building.

The alternative was to rotate the sample (this was in the days before high-pressure swivels and couplings were available) and align the jet just off the axis of rotation, so that the jet cut a hole somewhat wider than itself, as it passed over the target and thus provided an open path for the rebounding spent water that did not interfere with the path of the fresh jet travelling to the impact point.

A comparison of relative penetration rates showed that while a fixed nozzle and steady jet had sensibly stopped penetrating after about a second, the pulsed jet continued to drill a hole, as did the rotating jet, but the latter was able to drill faster and remove more material.

Figure 2. Comparison of a steady jet, a pulsating jet and a rotating jet as they penetrate into rock over time. All jets are at the same diameter, pressure and standoff distance.

By moving the nozzle out to a greater radius the hole created could be enlarged. This allowed the nozzle to move forward into the cavity created and the process could be repeated. In this way, over several iterations, a waterjet at a pressure of about 9,500 psi drilled though a block of granite, uniaxial compressive strength around 30,000 psi, and a new drilling tool had been demonstrated.

Obviously it is impractical to keep enlarging the hole by reaming it wider from the surface to allow the nozzle body to enter the hole and advance to the bottom. The jet must, from the beginning, drill a hole large enough for the nozzle to advance. And the easy way to do this is to incline the nozzle (at an optimal angle of around 20 deg, depending on the pressure, the type of waterjet and the target material properties). And while we still did not have a rotating swivel, we could turn and raise the target, while directing the jet through a small inclined orifice.

Figure 3. Inclined jet drilling a hole through a rock

Skip forward a couple of years, and we were drilling rock, at a rate of about 4-inches a minute, with a single jet. Then Jim Blaine, the RMERC machinist at the time, misunderstood a drawing, and added a central axially aligned orifice to the nozzle geometry. And within days we had increased the speed of drilling by two orders of magnitude. (Though by this time we also had a working rotating coupling to help rotate the nozzle).

Figure 4. Modified drill nozzle geometry

Figure 5. Drilling rate of advance as a function of hole diameter and rotation speed.

When one is using a single jet to cut the required profile of the hole, which must exceed the diameter of the nozzle holder if the drill is to advance into the hole, the rotation speed of the drill must be fast enough, relative to the rotation that the ribs of material left between adjacent passes of the jet along the hole wall are either non-existent (where the adjacent passes overlap) or are small enough that the mechanical impact of the nozzle body can break them off with very little force. In the latter case, however, this can put a mechanical load onto the drill string. The drill is often made up of only a length of high-pressure tubing, with the nozzle threaded on the end, so that any significant mechanical force can distort it and cause the drill to misalign and no longer drill a straight hole, so that this contact is discouraged.

On the other hand the rock through which the drill passes will likely change in strength and composition quite frequently, and so the depth to which the jet will cut will also change. This means that the hole diameter may reduce, so that the hole is no longer large enough to allow the nozzle body to pass. To stop this becoming a problem a small ring is mounted ahead of the nozzle, in the plane that the jet reaches the hole diameter required in this particular case. Now when the jet fails to cut to that diameter then the ring will stop the drill advancing, while the jet cuts along the line of contact and enlarges the hole to the required size, then allowing the drill to move forward. This is helped where the drill is spring-loaded so that the compression of the spring stops the drill advance, and the relaxing of the spring, as the obstacle is removed, allows the drill to move forward again.

Figure 6. Gaging ring on the front of a drilling nozzle.

That drill development was relatively straightforward, and was demonstrated in the late 1970’s. Subsequently commercial drilling systems were developed that used high-pressure water to drill holes in mine rock. They had the advantage over conventional tools in that the hose feeding the nozzle could maneuver in a much smaller space than a conventional drill, and thus longer holes could be more easily drilled from narrow working areas.

Unfortunately it still proved difficult to drill all rock with a plain waterjet, despite the use of ultra-high pressure equipment, and two different approaches were then tried, which I will discuss in the next posts.

Read more!

Sunday, March 1, 2015

Waterjetting 30d - Applying cavitation damage

Much of the work that we carry out with high pressure waterjets requires that they cut with precision and, in consequence much of the focus has been on controlling the stream of the jet to obtain the tightly constrained cutting action that produces this result.

Yet two of the larger growth sectors of the industry, the sub-divisions that have now been given the titles “hydro-demolition” and “hydro-excavation” don’t have that focus. Rather they seek to remove critical volumes of material, generally to some specific depth, but with less concern over the edges of the hole that is being created (provided water doesn’t penetrate the edge materials).

Depth of cut control is a little more of a challenge using an abrasive waterjet system since I have seen AWJ cuts that penetrated through feet of reinforced concrete and have mentioned the problem that new owners of systems sometimes run into when they run the nozzle for too long in a fixed position over a target and discover that the jet has not only cut the material, but also penetrated through the bottom of the holding tank, and put a hole into the underlying concrete floor.

Precisely controlling depth then becomes a matter of controlling the length of time the jet cuts on a surface, and to get to a fixed depth that will also depend on the amount of abrasive in the water, the jet pressure and the distance from the nozzle to the surface. It can also, to a degree, be controlled by the pressure of the surrounding fluid, although that is an interaction with the driving pressure that can become a little more complex.

In the last post I mentioned that when cavitation is formed around the outside of a jet cutting down through water which is itself pressurized (perhaps only because the jet is under a significant depth as water, such as for example a diver cutting apart an oil platform in the North Sea) then the damage from the cavitation bubble collapse occurs most intensely over a short distance from the nozzle. That distance changes with the cavitation number (simplistically the ratio of the pressure in the water around the jet to the pressure driving the jet itself), the volume flow and in a secondary relationship to the surrounding fluid pressure as well as other factors.

The latter impact of chamber pressure on the cutting range of the jet can be demonstrated with a Lichtarowicz cell, which allows one to see the jet as it cuts through surrounding fluid to the jet, and where, by adjusting the chamber fluid pressure the jet and cavitation cloud length can be extended to and beyond the sample, or reduced so that the jet barely reaches the target.

Figure 1. Backlit picture showing the cavitation bubbles forming and hitting the target.

The problem with generating this type of cavitation cloud as a means of drilling forward is that the bubbles are on the outside of the jet, and so as the jet hits and flows across the surface it protects the surface from the bubbles which flow on the outside of the lateral action.

The bubbles need to be confined against the target surface, and this is easier to do where the bubbles are formed in the center of the jet. The ways of doing this were discussed in an earlier post but can be summarized as being either by creating a turbulent swirl in the jet, or by placing a flat-ended probe into the jet stream.

Figure 2. Methods of creating cavitation bubbles in the center of a jet. (After Johnson et al)

Of these two methods, that using the central probe is more effective over greater distances, since the jet remains relatively coherent, while the swirling jet tends to broaden and lose energy after much shorter distances.

Tests of the central probe device showed that it could very quickly drill a hole more than 18 inches deep – at which point, unfortunately, the probe within the nozzle was itself destroyed by the cavitation action.

These tests were, however, carried out with nozzles with orifice diameters on the order of 0.04 inches, with the probe diameter being roughly half of that. Such designs are difficult to make and then align – ensuring that the probe is centered within the orifice throat, as shown.

In contrast with abrasive waterjet damage, the damage from an individual event is not as critically affected by the particle size nor by the main jet velocity. The collapsing pressure jet from a cavity collapse is at around 1 million psi – as Dr. Al Ellis theorized and we were able to confirm at Missouri S&T. This occurs with relatively little control by the surrounding fluid, or originating jet (which instead is more influential in controlling the intensity of cavitation generation and the location of the collapse).

This means that it is quite possible to use larger jet streams and still achieve quite destructive effects. In Johnson’s early paper on the topic he was using a jet pressure of 1,600 psi and able to drill through blocks of granite. The best advance rate that he could achieve at that time was around 3.5 inches/hour – which is not a practical value for commercial operations.

And unfortunately, for a while, this led us to be distracted into seeking higher and higher operating pressures to drive the jet, forgetting that this did not really change the bubble collapse pressure. It was only later, when we followed Dr. Lichtarowicz’ advice that we started adjusting the back pressure in the system and then we began to achieve useful material removal rates (on the order of cubic inches per minute).

However we did not carry out tests at larger flow rates, where we know, from the evidence at the Tarbela High Dam that much greater volumes of material may be removed, even at relatively low operating pressures.

At the Boulder Dam in the United States cavitation generated a cavity some 100 ft long and roughly 25 ft wide cutting into the rock wall to a depth of 40 ft. along the spillway during the course of a season, as reported by Warnock.

As a result of these tests it is clear that there is a considerable development potential for the practical use of cavitation – at significantly higher production rates than achieved to date, and over the wide spectrum of minerals (since the high destructive pressures exceed those necessary to disintegrate all natural materials).

It will be interesting to see when interest in the topic regenerates.

Johnson, Kohl, Thiruvengadam and Conn “Tunneling, Fracturing, Drilling and Mining with High-Speed Waterjets Utilizing Cavitation Damage.” First ISJCT

Benjamin T.B. and Ellis A.T. “The Collapse of Cavitation Bubbles and the Pressures Thereby Produced against Solid Boundaries,’ Proc. Royal Society (London), A262, pp.221-240.

Wanock J.E. “Experiences in the Bureau of Reclamation,” Cavitation in Hydraulic Structures – a Symposium, ASCE vol 71, no 7, p 1053. (Sept. 1945)

Yet two of the larger growth sectors of the industry, the sub-divisions that have now been given the titles “hydro-demolition” and “hydro-excavation” don’t have that focus. Rather they seek to remove critical volumes of material, generally to some specific depth, but with less concern over the edges of the hole that is being created (provided water doesn’t penetrate the edge materials).

Depth of cut control is a little more of a challenge using an abrasive waterjet system since I have seen AWJ cuts that penetrated through feet of reinforced concrete and have mentioned the problem that new owners of systems sometimes run into when they run the nozzle for too long in a fixed position over a target and discover that the jet has not only cut the material, but also penetrated through the bottom of the holding tank, and put a hole into the underlying concrete floor.

Precisely controlling depth then becomes a matter of controlling the length of time the jet cuts on a surface, and to get to a fixed depth that will also depend on the amount of abrasive in the water, the jet pressure and the distance from the nozzle to the surface. It can also, to a degree, be controlled by the pressure of the surrounding fluid, although that is an interaction with the driving pressure that can become a little more complex.

In the last post I mentioned that when cavitation is formed around the outside of a jet cutting down through water which is itself pressurized (perhaps only because the jet is under a significant depth as water, such as for example a diver cutting apart an oil platform in the North Sea) then the damage from the cavitation bubble collapse occurs most intensely over a short distance from the nozzle. That distance changes with the cavitation number (simplistically the ratio of the pressure in the water around the jet to the pressure driving the jet itself), the volume flow and in a secondary relationship to the surrounding fluid pressure as well as other factors.

The latter impact of chamber pressure on the cutting range of the jet can be demonstrated with a Lichtarowicz cell, which allows one to see the jet as it cuts through surrounding fluid to the jet, and where, by adjusting the chamber fluid pressure the jet and cavitation cloud length can be extended to and beyond the sample, or reduced so that the jet barely reaches the target.

Figure 1. Backlit picture showing the cavitation bubbles forming and hitting the target.

The problem with generating this type of cavitation cloud as a means of drilling forward is that the bubbles are on the outside of the jet, and so as the jet hits and flows across the surface it protects the surface from the bubbles which flow on the outside of the lateral action.

The bubbles need to be confined against the target surface, and this is easier to do where the bubbles are formed in the center of the jet. The ways of doing this were discussed in an earlier post but can be summarized as being either by creating a turbulent swirl in the jet, or by placing a flat-ended probe into the jet stream.

Figure 2. Methods of creating cavitation bubbles in the center of a jet. (After Johnson et al)

Of these two methods, that using the central probe is more effective over greater distances, since the jet remains relatively coherent, while the swirling jet tends to broaden and lose energy after much shorter distances.

Tests of the central probe device showed that it could very quickly drill a hole more than 18 inches deep – at which point, unfortunately, the probe within the nozzle was itself destroyed by the cavitation action.

These tests were, however, carried out with nozzles with orifice diameters on the order of 0.04 inches, with the probe diameter being roughly half of that. Such designs are difficult to make and then align – ensuring that the probe is centered within the orifice throat, as shown.

In contrast with abrasive waterjet damage, the damage from an individual event is not as critically affected by the particle size nor by the main jet velocity. The collapsing pressure jet from a cavity collapse is at around 1 million psi – as Dr. Al Ellis theorized and we were able to confirm at Missouri S&T. This occurs with relatively little control by the surrounding fluid, or originating jet (which instead is more influential in controlling the intensity of cavitation generation and the location of the collapse).

This means that it is quite possible to use larger jet streams and still achieve quite destructive effects. In Johnson’s early paper on the topic he was using a jet pressure of 1,600 psi and able to drill through blocks of granite. The best advance rate that he could achieve at that time was around 3.5 inches/hour – which is not a practical value for commercial operations.

And unfortunately, for a while, this led us to be distracted into seeking higher and higher operating pressures to drive the jet, forgetting that this did not really change the bubble collapse pressure. It was only later, when we followed Dr. Lichtarowicz’ advice that we started adjusting the back pressure in the system and then we began to achieve useful material removal rates (on the order of cubic inches per minute).

However we did not carry out tests at larger flow rates, where we know, from the evidence at the Tarbela High Dam that much greater volumes of material may be removed, even at relatively low operating pressures.

At the Boulder Dam in the United States cavitation generated a cavity some 100 ft long and roughly 25 ft wide cutting into the rock wall to a depth of 40 ft. along the spillway during the course of a season, as reported by Warnock.

As a result of these tests it is clear that there is a considerable development potential for the practical use of cavitation – at significantly higher production rates than achieved to date, and over the wide spectrum of minerals (since the high destructive pressures exceed those necessary to disintegrate all natural materials).

It will be interesting to see when interest in the topic regenerates.

Johnson, Kohl, Thiruvengadam and Conn “Tunneling, Fracturing, Drilling and Mining with High-Speed Waterjets Utilizing Cavitation Damage.” First ISJCT

Benjamin T.B. and Ellis A.T. “The Collapse of Cavitation Bubbles and the Pressures Thereby Produced against Solid Boundaries,’ Proc. Royal Society (London), A262, pp.221-240.

Wanock J.E. “Experiences in the Bureau of Reclamation,” Cavitation in Hydraulic Structures – a Symposium, ASCE vol 71, no 7, p 1053. (Sept. 1945)

Read more!

Wednesday, February 18, 2015

Waterjetting 30b - An opportunity missed, and a question raised

In the last post I wrote about the benefits of cutting a deep slot around the edges of a tunnel, and made reference to the work done here by Dr. El-Saie back in the mid-1970’s as part of his Doctoral Dissertation.

One of the concerns that we had to address was that the waterjet had to be able to penetrate all the different rock types that it might encounter, and at the same time, since the jet would only cut a short depth on each pass we also had to find a way of cutting the slot wide enough that the nozzle assembly could enter and deepen the slot over consecutive passes around the edge. Given that the available pressures in those days were limited, for us, to 30,000 psi and this pressure was insufficient, by itself, to cut through all the rocks we might encounter, Dr. El-Saie looked at several different ways of enhancing performance. These included adding abrasive to a high pressure jet stream, inducing cavitation into the jet stream and the potential for using the break-up of the jet into droplets to enhance cutting using the impact water hammer effect.

Because of other operating conditions it was not considered practical to try and develop the droplet impact idea for this program, and the work concentrated on examining the potential differences between abrasive waterjet injection and cavitation. To simplify the comparison the same basic nozzle design was used for the tests that were then run, although the shroud fitted to create the secondary (vacuum) chamber was modified to either allow abrasive entrainment, through ports, or to create cavitation. The presence of the ports did, however, allow the strength of the vacuum generated in the chamber to be measured as the jet passed through.

Figure 1. Nozzle designs used by Dr. El-Saie. Note that the upper design has ports leading into the vacuum chamber, so that abrasive can be drawn in by the jet passage. In the lower design there are no ports, and cavitation will be induced in the chamber by the jet passage, with the bubbles then drawn into the exiting jet.

One of the advantages of cavitating the jets is that the cavitation bubble collapse will spread out over a larger area on the target surface, so that the slot generated can be quite a bit larger than the originating jet. This can be shown in two pictures of a block of dolomite exposed to the same cavitating jet, at a pressure of 6,000 psi but one with the jet traversed along the block in a minute, while in the second case the jet is moved at a slower speed, taking five minutes to cross the block, which allows the jet to exploit the cracks generated by the cavitation. A fuller description of the process is given here.

Figure 2. Cavitation damage pattern on a block of dolomite showing the initial width of the jet (red lines), and the zone of damage that is being created around the traverse path.

Figure 3. Cavitation damage on a block of dolomite at a slower traverse speed, showing the width of the damage track that can be created. The slot is about half-an-inch deep.

In the course of the test program different shroud shapes were tested, but in all cases the comparison between an abrasive-laden jet and one containing cavitation bubbles was made with shroud shapes of the same overall dimensions.

The ratio of the exit diameter (discharge) from the shroud (D2) to that of the initial jet orifice (D1) was first changed to one of four different ratios, though the diameter of the initial jet was kept at 0.04 inches (1 mm). Of the different sizes tested the greatest vacuum in the chamber was measured with the smallest of the discharge diameters was tested.

Figure 4. The effect of increasing the throat length of the shroud on the vacuum pilled in the chamber, at different pressures.

If the discharge diameter was increased to 6.35 mm then the jet pressure had to be increased to 12,500 psi to obtain the same levels of vacuum achieved otherwise at 7,500 psi.

Figure 5. Vacuum pressures measured with a larger discharge diameter from the shroud, for different lengths and jet pressures.

Impact force measurements from the jet hitting a target at varying distances from the orifice, with and without the shroud showed relatively little difference in the overall total impact force (not considering abrasive) out to a distance of 6 inches. There was thus no apparent effect due to jet disintegration from the use of the shroud over these distances.

In order to compare the performance of the abrasive-laden jet with that of a cavitating jet, a new nozzle design was developed, and small samples of granite were rotated in front of each nozzle assembly, for 20 seconds. Because the jet had to be brought up to pressure for each test, and shut down afterwards, a steel shutter plate was placed between the nozzle and the target. One of the irritants in doing the tests was that the jets kept cutting through this shutter plate.

Figure 6. Steel shutter plate cut through in 6 seconds during system start-up.

The shroud, made of stainless steel, was also wearing out within a few minutes. Unfortunately we did not recognize that this was demonstrating that abrasive waterjets were an effective method for cutting metal – that commercial development had to wait for the more perspicacious Dr. Hashish to work with Flow Research and bring the technology to the market in 1980.

Part of the reason for our lack of interest was because of a different conclusion that Dr. El-Saie drew from his work, based on the following two curves. The first comparison of different jet results occurred with a jet pressure of 7,000 psi.

Figure 7. Volume of material removed from granite samples, as a function of distance, for four different jet conditions at a jet pressure of 7,000 psi.

Note that the three water jets do not have much significant effect on the granite at this distance and jet pressure (we had to learn some later lessons to make them more productive at this pressure). But even at this pressure the abrasive waterjet was effectively cutting the granite.

But it was the change in the relative position of these curves, as the pressure was then increased to 20,000 psi that caught our attention. (The intermediate plots are not given here).

Figure 8. Volume of material removed from granite samples, as a function of distance, for four different jet conditions at a jet pressure of 20,000 psi.

The water feed was not useful, since the power required to accelerate that volume drew heavily from that available through the jet.

The plain jet, without a shroud will cut granite at this pressure, particularly when moved over the surface. (And we later used this system to carve the Millennium Arch_ – as well as the Missouri Stonehenge). But the performance at that time was not that impressive.

Opening the ports on the shroud, without feeding anything into the jet caused, we believed a greater jet breakup and thus some additional droplet impact effects that improved cutting performance over that of the plain, more coherent jet, in part because the jet was spread over a larger contact surface.

Closing the jets induced cavitation in the stream, and this gave the best performance of the four – including abrasive injection. Again this was, in part because of the larger area of damage that the cavitation generated on the target, over the narrower slot of the abrasive-laden and plain jets.

In comparison the abrasive waterjet did rather poorly. In retrospect this is perhaps more of a surprise – but it should be born in mind that there was little attempt at optimizing the feed condition (which later research shows has a dramatic effect on performance) or the chamber geometry. Further the slot cut was much narrower than that created by the cavitating jet.

But it certainly caused us, in that time interval, to look more at cavitation, and to totally miss the implications of the AWJ result.

Most of these illustrations come from the Doctoral Dissertation by Dr. A. A. El-Saie “Investigation of Rock Slotting by High Pressure Waterjet for Use in Tunneling”, Mining Engineering Department, Missouri University of Science and Technology, (Then University of Missouri-Rolla), 1977.

One of the concerns that we had to address was that the waterjet had to be able to penetrate all the different rock types that it might encounter, and at the same time, since the jet would only cut a short depth on each pass we also had to find a way of cutting the slot wide enough that the nozzle assembly could enter and deepen the slot over consecutive passes around the edge. Given that the available pressures in those days were limited, for us, to 30,000 psi and this pressure was insufficient, by itself, to cut through all the rocks we might encounter, Dr. El-Saie looked at several different ways of enhancing performance. These included adding abrasive to a high pressure jet stream, inducing cavitation into the jet stream and the potential for using the break-up of the jet into droplets to enhance cutting using the impact water hammer effect.

Because of other operating conditions it was not considered practical to try and develop the droplet impact idea for this program, and the work concentrated on examining the potential differences between abrasive waterjet injection and cavitation. To simplify the comparison the same basic nozzle design was used for the tests that were then run, although the shroud fitted to create the secondary (vacuum) chamber was modified to either allow abrasive entrainment, through ports, or to create cavitation. The presence of the ports did, however, allow the strength of the vacuum generated in the chamber to be measured as the jet passed through.

Figure 1. Nozzle designs used by Dr. El-Saie. Note that the upper design has ports leading into the vacuum chamber, so that abrasive can be drawn in by the jet passage. In the lower design there are no ports, and cavitation will be induced in the chamber by the jet passage, with the bubbles then drawn into the exiting jet.

One of the advantages of cavitating the jets is that the cavitation bubble collapse will spread out over a larger area on the target surface, so that the slot generated can be quite a bit larger than the originating jet. This can be shown in two pictures of a block of dolomite exposed to the same cavitating jet, at a pressure of 6,000 psi but one with the jet traversed along the block in a minute, while in the second case the jet is moved at a slower speed, taking five minutes to cross the block, which allows the jet to exploit the cracks generated by the cavitation. A fuller description of the process is given here.

Figure 2. Cavitation damage pattern on a block of dolomite showing the initial width of the jet (red lines), and the zone of damage that is being created around the traverse path.

Figure 3. Cavitation damage on a block of dolomite at a slower traverse speed, showing the width of the damage track that can be created. The slot is about half-an-inch deep.

In the course of the test program different shroud shapes were tested, but in all cases the comparison between an abrasive-laden jet and one containing cavitation bubbles was made with shroud shapes of the same overall dimensions.

The ratio of the exit diameter (discharge) from the shroud (D2) to that of the initial jet orifice (D1) was first changed to one of four different ratios, though the diameter of the initial jet was kept at 0.04 inches (1 mm). Of the different sizes tested the greatest vacuum in the chamber was measured with the smallest of the discharge diameters was tested.

Figure 4. The effect of increasing the throat length of the shroud on the vacuum pilled in the chamber, at different pressures.

If the discharge diameter was increased to 6.35 mm then the jet pressure had to be increased to 12,500 psi to obtain the same levels of vacuum achieved otherwise at 7,500 psi.

Figure 5. Vacuum pressures measured with a larger discharge diameter from the shroud, for different lengths and jet pressures.

Impact force measurements from the jet hitting a target at varying distances from the orifice, with and without the shroud showed relatively little difference in the overall total impact force (not considering abrasive) out to a distance of 6 inches. There was thus no apparent effect due to jet disintegration from the use of the shroud over these distances.

In order to compare the performance of the abrasive-laden jet with that of a cavitating jet, a new nozzle design was developed, and small samples of granite were rotated in front of each nozzle assembly, for 20 seconds. Because the jet had to be brought up to pressure for each test, and shut down afterwards, a steel shutter plate was placed between the nozzle and the target. One of the irritants in doing the tests was that the jets kept cutting through this shutter plate.

Figure 6. Steel shutter plate cut through in 6 seconds during system start-up.

The shroud, made of stainless steel, was also wearing out within a few minutes. Unfortunately we did not recognize that this was demonstrating that abrasive waterjets were an effective method for cutting metal – that commercial development had to wait for the more perspicacious Dr. Hashish to work with Flow Research and bring the technology to the market in 1980.

Part of the reason for our lack of interest was because of a different conclusion that Dr. El-Saie drew from his work, based on the following two curves. The first comparison of different jet results occurred with a jet pressure of 7,000 psi.

Figure 7. Volume of material removed from granite samples, as a function of distance, for four different jet conditions at a jet pressure of 7,000 psi.

Note that the three water jets do not have much significant effect on the granite at this distance and jet pressure (we had to learn some later lessons to make them more productive at this pressure). But even at this pressure the abrasive waterjet was effectively cutting the granite.

But it was the change in the relative position of these curves, as the pressure was then increased to 20,000 psi that caught our attention. (The intermediate plots are not given here).

Figure 8. Volume of material removed from granite samples, as a function of distance, for four different jet conditions at a jet pressure of 20,000 psi.

The water feed was not useful, since the power required to accelerate that volume drew heavily from that available through the jet.

The plain jet, without a shroud will cut granite at this pressure, particularly when moved over the surface. (And we later used this system to carve the Millennium Arch_ – as well as the Missouri Stonehenge). But the performance at that time was not that impressive.

Opening the ports on the shroud, without feeding anything into the jet caused, we believed a greater jet breakup and thus some additional droplet impact effects that improved cutting performance over that of the plain, more coherent jet, in part because the jet was spread over a larger contact surface.

Closing the jets induced cavitation in the stream, and this gave the best performance of the four – including abrasive injection. Again this was, in part because of the larger area of damage that the cavitation generated on the target, over the narrower slot of the abrasive-laden and plain jets.

In comparison the abrasive waterjet did rather poorly. In retrospect this is perhaps more of a surprise – but it should be born in mind that there was little attempt at optimizing the feed condition (which later research shows has a dramatic effect on performance) or the chamber geometry. Further the slot cut was much narrower than that created by the cavitating jet.

But it certainly caused us, in that time interval, to look more at cavitation, and to totally miss the implications of the AWJ result.

Most of these illustrations come from the Doctoral Dissertation by Dr. A. A. El-Saie “Investigation of Rock Slotting by High Pressure Waterjet for Use in Tunneling”, Mining Engineering Department, Missouri University of Science and Technology, (Then University of Missouri-Rolla), 1977.

Read more!

Friday, November 28, 2014

Waterjetting 27d: Drilling at a fixed diameter

In the last post I described how we initially came up with a simple design for drilling through material, using an axially aligned jet and a larger jet offset to one side at an optimal angle of around 20 degrees.

One of the problems with the use of this design is that the outer jet has to remove all the material in front of the nozzle during the time that it rotates around and advances the distance of the incremental feed rate. If it does not then there is a significant problem. Consider the case where the drill penetrates through a layer of limestone, while drilling otherwise in sandstone.

Figure 1. Sectioned waterjet drilled hole through a sandstone:limestone:sandstone sandwich of rock.

Note that although the hole does not deviate as it goes through the harder material since, unlike conventional drills, there is no mechanical contact between the high-angled rock and the nozzle assembly. But the hole reduces in size. If the hole reduces in size below the diameter of the nozzle holder, this will not contact the rock until it has passed behind the plane of the reaming jet. In other words the only way the blocking rock can be removed is to back the nozzle along the hole so that the reaming jet can hit the material blocking progress.

Figure 2. Drill passage blocked by protruding rock in the path of the nozzle body, but behind the cutting plane of the inclined jet.

One way to ensure that this is not a problem is to advance the drill at a slower rate, with the rate of penetration controlled by the ability to cut the hardest rock that the drill will pass through. The problem with that approach, and concurrently that of setting a fixed advance rate, is that, at the same advance rate and rotation speed, the drill will drill through different rocks at a different diameter. While this can be an advantage, in a limited number of cases that I will discuss in a later post, in most cases it is better if the hole is at a relatively constant diameter.

So how can we solve this problem?

One approach taken in Australia was to change the design and location of the cutting jets. Rather than have a single jet cutting out to the perimeter of the hole, two jets were used, but crossed over the axis and cut on the opposite side to their location. This had an additional advantage over the initial design in that, when drilling longer holes (and this went on to drill horizontal holes that ranged up to a kilometer in length IIRC) the head was balanced and so did not wobble and get out of alignment because of the force imbalance.

To overcome the problem of drilling at too small a diameter additional reaming jets were placed on the front of the nozzle assembly, so that he hole would be reamed to the diameter needed to allow the support hose access.

Figure 3. The addition of a pair of reaming jets. Note that offsetting the two front nozzles will also allow them to put a torque on the front part of the nozzle, which can therefore be self-rotating from the left hand of arrow A forward.

But the problem is not completely solved with these changes, since should any rock protrude into the hole in the distance A, so that it hits the larger diameter that follows, again it is not possible for the reaming jets to cut this rock without backing up the drill.

There is another problem, in drilling horizontal holes where the hole diameter can vary. Consider that if the drill goes into a softer material then, at constant advance (ROP), the hole diameter becomes larger. As the drill moves over this larger hole it will be riding on the floor of the hole, and thus the front of the drill will tip forward into the floor of the larger hole. This will incline the drill downwards, and so the hole will no longer be of constant alignment, but rather will gradually, over distance, tip increasingly downwards.

It is therefore critical that the hole be drilled at a relatively constant diameter (allowing for some hole roughness). How to achieve this? The answer is to put a gaging ring or collar of the required hole diameter, in the cutting plane of the rotating jets.

Figure 4. The use of a collar at the front of the nozzle to ensure the hole is cut to the right diameter.

It itself this isn’t sufficient to give the hole a constant diameter, since there is still the problem of drilling through materials of differing resistance. To overcome that problem we put a spring at the back of the drill, with a contact switch to a valve on the feed to the hydraulic motor powering the drill advance. Thus the drill would start to rotate, and the motor would increase the speed of advance until the collar bumped up against the rock. At that time the spring would compress, the contact switch would close, and the advance would momentarily stop. The drill would rotate around and remove the obstructing rock, the spring would expand opening the flow to the motor, and the drill would move forward. It may sound as though it would be a stuttering advance, but when we tried it in a mine you couldn’t tell that the mechanism was working, apart from the hole being of constant diameter, and by watching the spring. It drilled at between 7 and 12 ft a minute in an aggressive sandstone.

Figure 5. The drill assembly used underground. The hydraulic advance motor (it pulls the drill forward using the chain drive) can be seen under the drill sash (the red and grey bar – painted in 1 ft intervals).

In a normal drilling operation when a drill intersects a previously drilled hole at a shallow angle, then the second drill will follow the path of the first hole, and cannot drill through the opposing wall at that shallow angle. (We know this from experience having broken two drill steels trying while excavating the OmniMax Theater under the Arch in St. Louis). But with the waterjet drill we were able to make to second drill cross the intersection.

Figure 6. Photo down one drill hole, showing the point where the hole intersected a second, and crossed without deviation.

Hopefully there is now enough background so that next time I can talk a little more about the effects of borehole pressure on drilling performance.

One of the problems with the use of this design is that the outer jet has to remove all the material in front of the nozzle during the time that it rotates around and advances the distance of the incremental feed rate. If it does not then there is a significant problem. Consider the case where the drill penetrates through a layer of limestone, while drilling otherwise in sandstone.

Figure 1. Sectioned waterjet drilled hole through a sandstone:limestone:sandstone sandwich of rock.

Note that although the hole does not deviate as it goes through the harder material since, unlike conventional drills, there is no mechanical contact between the high-angled rock and the nozzle assembly. But the hole reduces in size. If the hole reduces in size below the diameter of the nozzle holder, this will not contact the rock until it has passed behind the plane of the reaming jet. In other words the only way the blocking rock can be removed is to back the nozzle along the hole so that the reaming jet can hit the material blocking progress.

Figure 2. Drill passage blocked by protruding rock in the path of the nozzle body, but behind the cutting plane of the inclined jet.

One way to ensure that this is not a problem is to advance the drill at a slower rate, with the rate of penetration controlled by the ability to cut the hardest rock that the drill will pass through. The problem with that approach, and concurrently that of setting a fixed advance rate, is that, at the same advance rate and rotation speed, the drill will drill through different rocks at a different diameter. While this can be an advantage, in a limited number of cases that I will discuss in a later post, in most cases it is better if the hole is at a relatively constant diameter.

So how can we solve this problem?

One approach taken in Australia was to change the design and location of the cutting jets. Rather than have a single jet cutting out to the perimeter of the hole, two jets were used, but crossed over the axis and cut on the opposite side to their location. This had an additional advantage over the initial design in that, when drilling longer holes (and this went on to drill horizontal holes that ranged up to a kilometer in length IIRC) the head was balanced and so did not wobble and get out of alignment because of the force imbalance.

To overcome the problem of drilling at too small a diameter additional reaming jets were placed on the front of the nozzle assembly, so that he hole would be reamed to the diameter needed to allow the support hose access.

Figure 3. The addition of a pair of reaming jets. Note that offsetting the two front nozzles will also allow them to put a torque on the front part of the nozzle, which can therefore be self-rotating from the left hand of arrow A forward.

But the problem is not completely solved with these changes, since should any rock protrude into the hole in the distance A, so that it hits the larger diameter that follows, again it is not possible for the reaming jets to cut this rock without backing up the drill.

There is another problem, in drilling horizontal holes where the hole diameter can vary. Consider that if the drill goes into a softer material then, at constant advance (ROP), the hole diameter becomes larger. As the drill moves over this larger hole it will be riding on the floor of the hole, and thus the front of the drill will tip forward into the floor of the larger hole. This will incline the drill downwards, and so the hole will no longer be of constant alignment, but rather will gradually, over distance, tip increasingly downwards.

It is therefore critical that the hole be drilled at a relatively constant diameter (allowing for some hole roughness). How to achieve this? The answer is to put a gaging ring or collar of the required hole diameter, in the cutting plane of the rotating jets.

Figure 4. The use of a collar at the front of the nozzle to ensure the hole is cut to the right diameter.

It itself this isn’t sufficient to give the hole a constant diameter, since there is still the problem of drilling through materials of differing resistance. To overcome that problem we put a spring at the back of the drill, with a contact switch to a valve on the feed to the hydraulic motor powering the drill advance. Thus the drill would start to rotate, and the motor would increase the speed of advance until the collar bumped up against the rock. At that time the spring would compress, the contact switch would close, and the advance would momentarily stop. The drill would rotate around and remove the obstructing rock, the spring would expand opening the flow to the motor, and the drill would move forward. It may sound as though it would be a stuttering advance, but when we tried it in a mine you couldn’t tell that the mechanism was working, apart from the hole being of constant diameter, and by watching the spring. It drilled at between 7 and 12 ft a minute in an aggressive sandstone.

Figure 5. The drill assembly used underground. The hydraulic advance motor (it pulls the drill forward using the chain drive) can be seen under the drill sash (the red and grey bar – painted in 1 ft intervals).

In a normal drilling operation when a drill intersects a previously drilled hole at a shallow angle, then the second drill will follow the path of the first hole, and cannot drill through the opposing wall at that shallow angle. (We know this from experience having broken two drill steels trying while excavating the OmniMax Theater under the Arch in St. Louis). But with the waterjet drill we were able to make to second drill cross the intersection.

Figure 6. Photo down one drill hole, showing the point where the hole intersected a second, and crossed without deviation.

Hopefully there is now enough background so that next time I can talk a little more about the effects of borehole pressure on drilling performance.

Read more!

Sunday, November 23, 2014

Waterjetting 27c - Drilling nozzle design

In discussing how stress affects the ability of waterjets to drill rock, I have discussed the effect of the stress in the ground on drill performance, but before discussing the effect of the borehole pressure it is perhaps best to spend this post talking about the simplest drill bit design.

The diameter of the first jets we used to cut into rock were about 0.04 inches in size, with the nozzle holder used to hold the nozzle on the end of the supply pipe being at around an inch in diameter. As a result, if the jet was to cut a path into the rock, it would have to rotate around the face of the rock ahead of it, removing all the rock ahead of the assembly, and allowing the head to advance.

Figure 1. Original concept of a waterjet drill used to penetrate sandstone.

Of course, back when we first did this in the 1960’s the swivels weren’t available to allow us to rotate the high pressure line, and so we rotated the rock samples instead.

Figure 2. First holes drilled at the University of Leeds. Note the central cone.

Because the jet had to penetrate across the diameter of the hole, so as to remove the cone ahead of the tool, and since the jet would only cut around 2.5 times the jet diameter in width at any one time, the rate that the head could move forward was limited to a maximum of 0.1 x rotation speed (rpm) in inches/minute. And, because the rotation speed controlled the depth which the jet cut into the rock, the rpm had to be kept down to ensure that the jet cut to the full required diameter on each pass. The top speed we could achieve, even in relatively soft sandstone, was around 4 inches a minute.

One of those fortunate accidents that sometimes befalls research folk then occurred. I had asked Jim Blaine, our machinist, to make a new design, with one jet pointing forward and one off to the side, intending that the two be offset. However, due to a misunderstanding, he drilled the second, smaller hole along the jet axis, while offsetting the angled jet to cut further out from the diameter. Since the nozzle was built we proceeded to try it.

Figure 3. First dual jet nozzle design.

Because the axial jet removed the central core, we could offset the inclined jet so that it needed to cut a shorter distance in order to reach the required gage for the hole. That meant that we could rotate the nozzle faster, which in turn meant a faster drilling speed, much faster.

Figure 4. Hole diameter as a function of rate of penetration of the drill (in meters/minute), for two outer jet angles, and two rotation speeds.

Note that in the above figure, with a 30 degree outer jet, spinning at 970 rpm we were able to drill a hole at a speed of roughly 280 inches/minute instead of the previous 4 inches/min by adding only 25% more water to the bit with the second orifice.

As mentioned above, the limit on the advance rate was the depth which the jet cut into the wall, and the amount of rib between adjacent passes that the jet cut would leave.

Figure 5. An early hole drilled into Berea sandstone, at a slow advance rate, using a 10 ksi jet pressure.

Figure 6. Hole drilled into Berea sandstone at 970 rpm, 225 ipm advance rate, with a 15-degree inclined jet. Note that the hole perimeter has the equivalent of a thread cut into it.

It is pertinent to make a small observation over the advantage of that slightly roughened outer wall to the borehole. One of the ways in which miners hold up the roof while they are working underground, is to insert rods (known as roofbolts or rockbolts) into drilled holes placed in the surrounding rock. To improve the grip between these bolts and the wall, miners will also often insert packages of glue into the hole to fill the gap between the bolts and the rock wall.

Unfortunately when the hole is drilled with a conventional mechanical drilling bit, the walls of the hole are left relatively smooth. This means that the bolt has a poorer grip on the wall, and is more easily pulled out of the hole. The US Bureau of Mines ran anchorage tests for different rock wall finishes.

Figure 7. Effect of hole roughness on the anchor strength (US Bureau of Mines)

Conventionally a larger hole, with greater bearing surface, would give a stronger anchorage. This is shown by the greater load carried by the hole drilled with the 1-3/8th bit, over that drilled by the 1-1/4 inch bit. But both of these were smooth walled, and the bit drilled at 1-inch, with a roughened wall had almost three-times the pull strength even though of smaller size.

The roughness of the hole can be controlled by adjusting the feed rate, relative to the rotation speed, both as a function of the jet pressure, nozzle diameter and outer jet angle. It turned out, through experiment, that the optimal angle for the jet was at around 22.5-degrees, depending on the type of rock in which the drill was working.

The effect of rock properties plays a very significant role in the performance of the drill. And it was very easy, early in the program, to show that the important rock parameter was not the compressive strength of the material. To show this we drilled through prepared samples of an Indiana limestone and a sandstone, both of which had approximately the same (uniaxial) compressive strength. The advance rate was kept constant, as was the rotation speed, as the drill penetrated from one rock into the other, and then the hole was cut in half (as were the samples shown above).

Figure 8. Hole drilled from limestone into sandstone.

Although the hole maintained alignment, drilling straight forward through the steep interface between the two rocks (a problem with some conventional drills) the hole diameter changed dramatically.

How we changed the design to maintain hole diameter, and, at the same time, adjusted for changing borehole depth will be discussed next time.

The diameter of the first jets we used to cut into rock were about 0.04 inches in size, with the nozzle holder used to hold the nozzle on the end of the supply pipe being at around an inch in diameter. As a result, if the jet was to cut a path into the rock, it would have to rotate around the face of the rock ahead of it, removing all the rock ahead of the assembly, and allowing the head to advance.

Figure 1. Original concept of a waterjet drill used to penetrate sandstone.

Of course, back when we first did this in the 1960’s the swivels weren’t available to allow us to rotate the high pressure line, and so we rotated the rock samples instead.

Figure 2. First holes drilled at the University of Leeds. Note the central cone.

Because the jet had to penetrate across the diameter of the hole, so as to remove the cone ahead of the tool, and since the jet would only cut around 2.5 times the jet diameter in width at any one time, the rate that the head could move forward was limited to a maximum of 0.1 x rotation speed (rpm) in inches/minute. And, because the rotation speed controlled the depth which the jet cut into the rock, the rpm had to be kept down to ensure that the jet cut to the full required diameter on each pass. The top speed we could achieve, even in relatively soft sandstone, was around 4 inches a minute.

One of those fortunate accidents that sometimes befalls research folk then occurred. I had asked Jim Blaine, our machinist, to make a new design, with one jet pointing forward and one off to the side, intending that the two be offset. However, due to a misunderstanding, he drilled the second, smaller hole along the jet axis, while offsetting the angled jet to cut further out from the diameter. Since the nozzle was built we proceeded to try it.

Figure 3. First dual jet nozzle design.

Because the axial jet removed the central core, we could offset the inclined jet so that it needed to cut a shorter distance in order to reach the required gage for the hole. That meant that we could rotate the nozzle faster, which in turn meant a faster drilling speed, much faster.

Figure 4. Hole diameter as a function of rate of penetration of the drill (in meters/minute), for two outer jet angles, and two rotation speeds.

Note that in the above figure, with a 30 degree outer jet, spinning at 970 rpm we were able to drill a hole at a speed of roughly 280 inches/minute instead of the previous 4 inches/min by adding only 25% more water to the bit with the second orifice.

As mentioned above, the limit on the advance rate was the depth which the jet cut into the wall, and the amount of rib between adjacent passes that the jet cut would leave.

Figure 5. An early hole drilled into Berea sandstone, at a slow advance rate, using a 10 ksi jet pressure.

Figure 6. Hole drilled into Berea sandstone at 970 rpm, 225 ipm advance rate, with a 15-degree inclined jet. Note that the hole perimeter has the equivalent of a thread cut into it.

It is pertinent to make a small observation over the advantage of that slightly roughened outer wall to the borehole. One of the ways in which miners hold up the roof while they are working underground, is to insert rods (known as roofbolts or rockbolts) into drilled holes placed in the surrounding rock. To improve the grip between these bolts and the wall, miners will also often insert packages of glue into the hole to fill the gap between the bolts and the rock wall.

Unfortunately when the hole is drilled with a conventional mechanical drilling bit, the walls of the hole are left relatively smooth. This means that the bolt has a poorer grip on the wall, and is more easily pulled out of the hole. The US Bureau of Mines ran anchorage tests for different rock wall finishes.

Figure 7. Effect of hole roughness on the anchor strength (US Bureau of Mines)

Conventionally a larger hole, with greater bearing surface, would give a stronger anchorage. This is shown by the greater load carried by the hole drilled with the 1-3/8th bit, over that drilled by the 1-1/4 inch bit. But both of these were smooth walled, and the bit drilled at 1-inch, with a roughened wall had almost three-times the pull strength even though of smaller size.

The roughness of the hole can be controlled by adjusting the feed rate, relative to the rotation speed, both as a function of the jet pressure, nozzle diameter and outer jet angle. It turned out, through experiment, that the optimal angle for the jet was at around 22.5-degrees, depending on the type of rock in which the drill was working.

The effect of rock properties plays a very significant role in the performance of the drill. And it was very easy, early in the program, to show that the important rock parameter was not the compressive strength of the material. To show this we drilled through prepared samples of an Indiana limestone and a sandstone, both of which had approximately the same (uniaxial) compressive strength. The advance rate was kept constant, as was the rotation speed, as the drill penetrated from one rock into the other, and then the hole was cut in half (as were the samples shown above).

Figure 8. Hole drilled from limestone into sandstone.

Although the hole maintained alignment, drilling straight forward through the steep interface between the two rocks (a problem with some conventional drills) the hole diameter changed dramatically.

How we changed the design to maintain hole diameter, and, at the same time, adjusted for changing borehole depth will be discussed next time.

Read more!

Saturday, October 25, 2014

Waterjetting 26c - Cutting tool shape

When it was first discovered that high-pressure waterjets could significantly improve the performance of mechanical cutting tools, whether in machining metal, or in cutting rock, it was anticipated that this would have a broad-ranging application. This has not been the case, and the reasons are varied, depending on the application, but quite often they relate to the way in which the mechanical tool was expected to work. The examples will, again, come from rock cutting, but also apply when cutting or machining other materials.

Figure 1. Three common types of picks used in cutting into stone for driving tunnels, or for cutting and mining coal.

The initial work of Mike Hood, in cutting quartzite, had used a relatively simple flat-faced bit that was dragged across the rock surface at a known depth of cut and directing s single, or pair of jets to cut along the line of contact between the rock and the carbide was relatively straightforward.

Figure 2. Locations of the jets for Mike Hood’s initial tests on improving jet performance. (Dr. Hood)

Getting the jets to cover the full zone of contact and rock crushing was critical to achieving the best results for the tests, and proved also effective when the cutting tools were tried in the field.

Figure 3. Relative normal forces on a cutting bit with change in the position of the jets assisting in the cutting of rock (Dr. Hood). Note that the machine stalled at 4 mm penetration without the jet assist (the black line).

The cutting picks that are more commonly used in softer rock, shown in figure 1, are not quite the same shape, nor have quite the same purpose. Early trials were with the forward attack pick, which through the early 1980’s was the most common design used.

Figure 4. Laboratory trials with a jet added to a forward attack pick

Rather than having a flat face, this pick has a wedge-shaped front face. This is so that, as the pick cuts into the rock, so the wedge shape pressing into that groove will put a high lateral load on the rock on either side of the cut, causing it to shear off the solid. Those chips can be seen to the front right of figure 4.

Where the jet cuts into and removes the crushed rock under the front of the bit, this allows the bit to make a deeper bite, and this, in turn, makes it more likely that the tool will make larger chips. This is not an unflawed benefit, particularly if the jetted slot now extends a little deeper than the tool.

Figure 5. Illustrating the wedging action of the tool in creating lateral chips beside the tool.

As the chips get larger so the force required to break them from the solid increases, and the actions do not occur symmetrically on each side of the tool. As a result the lateral loading on the tool becomes more significant, and because the process of chip forming and breakage is cyclic so there greater fluctuating forces make their way through the drive train back to the driving shaft and motors.

With most machine designs these fluctuating loads are, however, reduced in overall magnitude, because of the reduced forces needed to move the pick forward, without having to deal with the crushed material under the pick, which the water jet has removed, providing it is within about 1/10th of an inch of the cutting tool.

Achieving that positioning becomes a little more difficult with the transition to a radial pick, however there were additional problems with that intermediate design, particularly in harder rocks, where they wore out at rates as high as 7 picks per foot of advance. This led to the development of the point attack pick, as shown in figure 1.

This pick design has become the most popular for use in mining machines over the past 20-years. The round shape of the tool and shaft are designed so that, as the pick wears it will rotate in the holder, and this will spread the wear evenly around the tool, making it last longer – and in the case mentioned in the last paragraph a change to this design reduced pick costs to around 1 pick per foot of advance. But there are a couple of problems with adding waterjets to this tool.

Figure 6. Point attack tool geometry (Goktan and Gunes)

This geometry makes it very difficult to bring in a waterjet to hit the right point at the rock:tool contact, because of the double cone at the end of the tool. While the nozzle can be positioned so that it can direct a jet into the right point (for example by being at the point where α is in the figure) the problem arises with the size of the nozzle mounting block, and the small size of the jet, where a large number are being used to cover all the picks on the cutting head and total flow volume is limited. To fit the nozzle block means that it must be at a greater standoff distance from the point (perhaps four or five inches), while the small orifice size means that the effective range of the jet may be no more than an inch or two.

The change in pick design and the difficulty in adding waterjets to the new tool therefore led to a discontinuation of the trials of the combined system. This was unfortunate since the forward attack picks initially cut better than the point attack, but wore out more rapidly – hence the change. But with the addition of the waterjets the tool lifetime, and sharpness, was increased in some cases more than five-fold times, while the other benefits – such as the ability to use smaller machines to carry out similar performance – made capital investment less. But these events occurred at the wrong time, as the coal market was entering one of its down cycles as the developments were being made, and the technology was therefore not adopted.

I will conclude this small chapter next time, by addressing one of the answers to the problem of getting water to the point attack tool.

Figure 1. Three common types of picks used in cutting into stone for driving tunnels, or for cutting and mining coal.

The initial work of Mike Hood, in cutting quartzite, had used a relatively simple flat-faced bit that was dragged across the rock surface at a known depth of cut and directing s single, or pair of jets to cut along the line of contact between the rock and the carbide was relatively straightforward.

Figure 2. Locations of the jets for Mike Hood’s initial tests on improving jet performance. (Dr. Hood)

Getting the jets to cover the full zone of contact and rock crushing was critical to achieving the best results for the tests, and proved also effective when the cutting tools were tried in the field.

Figure 3. Relative normal forces on a cutting bit with change in the position of the jets assisting in the cutting of rock (Dr. Hood). Note that the machine stalled at 4 mm penetration without the jet assist (the black line).

The cutting picks that are more commonly used in softer rock, shown in figure 1, are not quite the same shape, nor have quite the same purpose. Early trials were with the forward attack pick, which through the early 1980’s was the most common design used.

Figure 4. Laboratory trials with a jet added to a forward attack pick

Rather than having a flat face, this pick has a wedge-shaped front face. This is so that, as the pick cuts into the rock, so the wedge shape pressing into that groove will put a high lateral load on the rock on either side of the cut, causing it to shear off the solid. Those chips can be seen to the front right of figure 4.

Where the jet cuts into and removes the crushed rock under the front of the bit, this allows the bit to make a deeper bite, and this, in turn, makes it more likely that the tool will make larger chips. This is not an unflawed benefit, particularly if the jetted slot now extends a little deeper than the tool.

Figure 5. Illustrating the wedging action of the tool in creating lateral chips beside the tool.

As the chips get larger so the force required to break them from the solid increases, and the actions do not occur symmetrically on each side of the tool. As a result the lateral loading on the tool becomes more significant, and because the process of chip forming and breakage is cyclic so there greater fluctuating forces make their way through the drive train back to the driving shaft and motors.

With most machine designs these fluctuating loads are, however, reduced in overall magnitude, because of the reduced forces needed to move the pick forward, without having to deal with the crushed material under the pick, which the water jet has removed, providing it is within about 1/10th of an inch of the cutting tool.

Achieving that positioning becomes a little more difficult with the transition to a radial pick, however there were additional problems with that intermediate design, particularly in harder rocks, where they wore out at rates as high as 7 picks per foot of advance. This led to the development of the point attack pick, as shown in figure 1.

This pick design has become the most popular for use in mining machines over the past 20-years. The round shape of the tool and shaft are designed so that, as the pick wears it will rotate in the holder, and this will spread the wear evenly around the tool, making it last longer – and in the case mentioned in the last paragraph a change to this design reduced pick costs to around 1 pick per foot of advance. But there are a couple of problems with adding waterjets to this tool.

Figure 6. Point attack tool geometry (Goktan and Gunes)

This geometry makes it very difficult to bring in a waterjet to hit the right point at the rock:tool contact, because of the double cone at the end of the tool. While the nozzle can be positioned so that it can direct a jet into the right point (for example by being at the point where α is in the figure) the problem arises with the size of the nozzle mounting block, and the small size of the jet, where a large number are being used to cover all the picks on the cutting head and total flow volume is limited. To fit the nozzle block means that it must be at a greater standoff distance from the point (perhaps four or five inches), while the small orifice size means that the effective range of the jet may be no more than an inch or two.

The change in pick design and the difficulty in adding waterjets to the new tool therefore led to a discontinuation of the trials of the combined system. This was unfortunate since the forward attack picks initially cut better than the point attack, but wore out more rapidly – hence the change. But with the addition of the waterjets the tool lifetime, and sharpness, was increased in some cases more than five-fold times, while the other benefits – such as the ability to use smaller machines to carry out similar performance – made capital investment less. But these events occurred at the wrong time, as the coal market was entering one of its down cycles as the developments were being made, and the technology was therefore not adopted.

I will conclude this small chapter next time, by addressing one of the answers to the problem of getting water to the point attack tool.

Read more!

Sunday, September 28, 2014

Waterjetting 25c - more thoughts on jet range

A single waterjet, whether with or without abrasive, will cut a tapering slot as it penetrates into a target material. This is because, as the jet penetrates into the surface, the outer edges of the jet lose their energy in cutting, and the narrower central core remains capable of cutting, on a continually narrowing path, as the cut deepens.

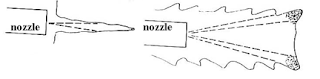

Figure 1 Tapered cut made with a single jet traverse in contrast with the wider cut made with two diverging jets.

While the above statement is generally true, it is not completely so, since if the speed of traverse of the jet is reduced, then the continued addition of further water along the cut plane will be sufficient for the outer layers of the jet to be able to continue to cut and this may reach the point that there is no taper along the edges of the slot, or it may even taper inwards. For an abrasive jet cutting into titanium, that transition occurs at around 0.2 inches/minute, depending on jet parameters. (Note that this is less related to the target thickness, although it is controlled by the cuttability of that material, and that the critical speeds for cutting with water along are at least one and often two orders of magnitude greater).

Figure 2. Plot of taper angle with traverse speed.

Unfortunately the speed at which the edge is cut perpendicular to the top surface of the target is usually too slow to be economic, and, in consequence, the normal process is to slightly tilt the cutting head into the edge with the desired surface, and making the opposing surface carry an exaggerated tilt. This then allows a faster cut, again with the optimal speed being a function of both tilt angle and jet parameters.